Variables Affecting Variety

The next is really a record on the facts required to help in building a coupling selection. Not all of those things will come into play in all choice processes. These products contain, but aren’t limited to:

Application associated:

Application information

Kind of motor and driven equipment

Motor horsepower or KW

Operating/coupling speed

Shaft sizes and separation

Area and size constraints

Atmosphere (temperature, chemical compounds, and so on)

Stability demands

Specific modifications

Actions In Deciding on A Gear Coupling

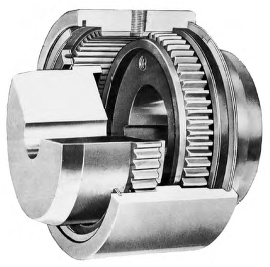

Refer for the gear coupling specifications charts displayed with every single style of coupling throughout the Gear Coupling Items section of this catalog. The pics and charts supply visualization, specs, and

Stage 1: Assessment the gear coupling series and style as selected to guarantee the selection

meets application specifications.

Stage two: Determine the nominal application torque in in-lbs by using the following formula:

Application Torque ( in-lb ) = (HP x 63025)/RPM

Or Nm = (KW x 9550)/RPM

Step three: Review the Application Services Component chart for your service component amount connected with all the application the place this coupling might be utilised. Multiply the application torque from the application services factor to determine the total torque essential to the coupling assortment.

Stage 4: Evaluate the needed complete torque worth with all the nominal torque capacity

listed while in the Gear Coupling Variety chart for that desired coupling variety.

Phase five: Verify the maximum bore size plus the optimum RPM with the coupling

sort chosen to ensure the coupling will meet these application demands.

Phase six: Note any distinctive prerequisites which includes the BSE dimension for floating shaft and spacer forms, shear pin torque, slide coupling particulars, mill motor tapered shaft data, and any other pertinent info.