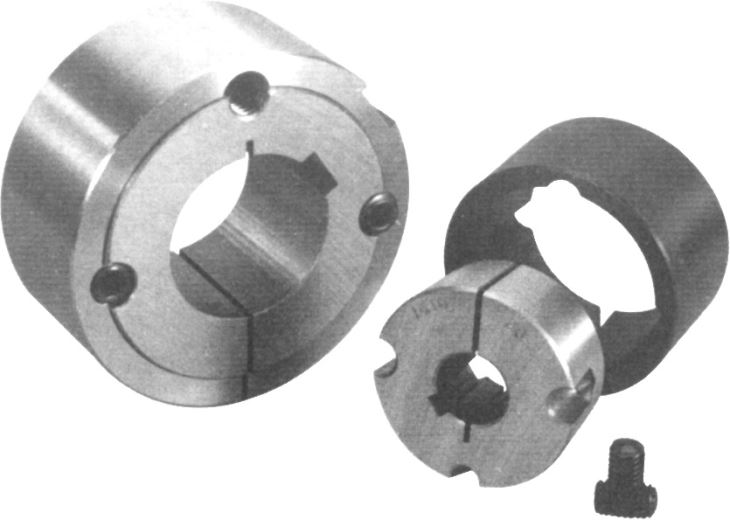

Taper Bore Adapters

Taperlock bushings are tapered non-flanged split bushings that utilize screws to tighten on the shaft, providing excellent clamping force. Taperlock bushings are utilized on sprockets, sheaves and pulleys to increase clamping force over standard bored to size product that only utilizes a keyway...

Taperlock bushings are tapered non-flanged split bushings that utilize screws to tighten on the shaft, providing excellent clamping force. Taperlock bushings are utilized on sprockets, sheaves and pulleys to increase clamping force over standard bored to size product that only utilizes a keyway and set screw to lock onto the shaft. Taperlock bushings are very popular and are interchangeable between manufacturers.

SPLIT TAPER BUSHINGS & HUBS

Split taper bushings are used to carry torque and mount pulleys, sprockets, and sheaves on shafts. They have a double-split barrel to provide flexibility and a strong hold on shafts. The barrel is keyed to the shaft to prevent rotation. Split taper bushings are also flanged to reduce drive vibration and provide a concentric bore. Unlike other bushings, they do not require a perfectly matched bored component and can accommodate shaft size changes without manual adjustment or replacement.

FAQ:

1.CAN YOU DO CUSTOMIZED PRODUCTS?

Yes,we are mainly doing customized products according to the customers’ drawings or samples.

2.HOW TO GUARANTEE THE QUALITY OF YOUR GOODS?

Firstly, We will do the inspection after every process.For the finished products,we will do 100% inspection according to the customers’ requirements and the international standard.Secondly,we have our own testing lab and the most advanced and complete inspection equipment in the casting industry,including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on.With these advanced facilities & instruments, we are able to supply the most precise finished products to our customers, and make products meeting their overall inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections.

3.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIF,CNF,etc.For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T. L/C is also acceptable.

Request a Brochure

and Samples

Request a Brochure

and Samples