Taper Bore Weld on Hubs(W Type )

Taperlock bushings are tapered non-flanged split bushings that utilize screws to tighten on the shaft, providing excellent clamping force. Taperlock bushings are utilized on sprockets, sheaves and pulleys to increase clamping force over standard bored to size product that only utilizes a keyway...

Taperlock bushings are tapered non-flanged split bushings that utilize screws to tighten on the shaft, providing excellent clamping force. Taperlock bushings are utilized on sprockets, sheaves and pulleys to increase clamping force over standard bored to size product that only utilizes a keyway and set screw to lock onto the shaft. Taperlock bushings are very popular and are interchangeable between manufacturers.

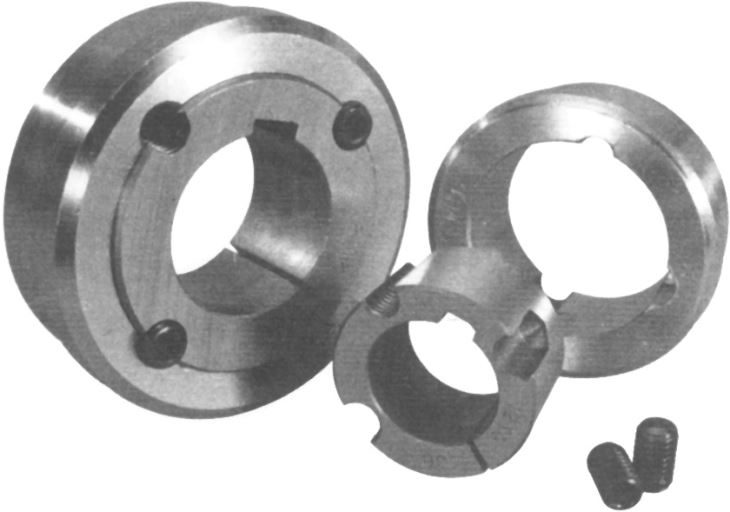

SPLIT TAPER BUSHINGS & HUBS

Split taper bushings are used to carry torque and mount pulleys, sprockets, and sheaves on shafts. They have a double-split barrel to provide flexibility and a strong hold on shafts. The barrel is keyed to the shaft to prevent rotation. Split taper bushings are also flanged to reduce drive vibration and provide a concentric bore. Unlike other bushings, they do not require a perfectly matched bored component and can accommodate shaft size changes without manual adjustment or replacement.

FAQ:

1.DO YOU HAVE SOME STANDARD PARTS?

Yes,besides the customized parts,we also can offer some standard parts which are mainly used for excavators.We called them G.E.T parts,including bucket teeth and adapters,cutting edges,side cutters,end bits,ripper shanks, shank guards and scarifies shanks,pins and retainers,bolts and nuts,etc.

2.HOW ABOUT THE CAPACITY OF YOUR COMPANY?

We have 12 modern types of energy-saving & environmentally-friendly production lines including a fully automated wax and shell making process flow line, as well as 4 heat treatment production lines. And our annual production capacity is over 20,000 tons.

3.HOW MANY EMPLOYEES OF YOUR COMANY?WHAT ABOUT THE TECHNICISTS?

We now have more than 650 employees, including 10 engineers and 50 technicians.

Request a Brochure

and Samples

Request a Brochure

and Samples