900 Class Sugar Mill Chains

900 SERIES PINTLE CHAINS, 901,902,907,5174. sometimes known as “sugar mill” or “intermediate carrier chain” is used extensively in sugar mills. Multiple strands of 900 Pintle Chain, available with a couple of holes per link, can be installed with overlapping beaded carrier slats to create a...

900 SERIES PINTLE CHAINS, 901,902,907,5174. sometimes known as “sugar mill” or “intermediate carrier chain” is used extensively in sugar mills. Multiple strands of 900 Pintle Chain,  available with a couple of holes per link, can be installed with overlapping beaded carrier slats to create a continuous apron conveyor for intermediate carrier provider.

available with a couple of holes per link, can be installed with overlapping beaded carrier slats to create a continuous apron conveyor for intermediate carrier provider.

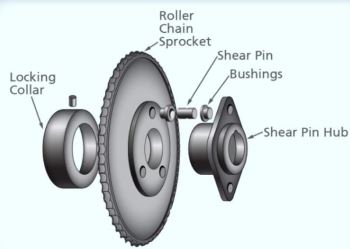

The pin holes at the closed end of the 900 Class link are provided with smooth bushings which are press-fitted into the links and keyed into place. The bushings are renewable and can be driven out and replaced when they become worn. 900 Class Pintle Chain is designed with dual barrels, one on each part of the open end of the links, to support double sprockets. The objective of this driving method is to get rid of the possibility of material build-up in the sprocket get in touch with area, which often causes the chain to leap the sprocket. Weighty ribs rigidly reinforce these traveling barrels.

Our 900 Class chain links, with tensile strength from 22,500 to 32,500 pounds, can be found with large sliding areas to lessen chain wear and prolong chain life. Broad wearing surfaces and heavy cross sections team up to provide a substantial link which is manufactured according to manufacturer’s standards and can perfectly replace links created by other manufacturers.

Brutaloy sprockets for 900 Class Pintle Chain are readily available in 3.170 inches. 900 Class Pintle Chain should only be allowed to travel in one direction; links should always run in the direction of their closed narrow end.

Obtainable in cottered construction only, 900 Class Chain can be assembled with T-headed pins which are locked into place by two lugs cast upon the ends of the driving barrels to prevent pin rotation. Pin rotation during operation would result in wear on the inside of the bushing. Both the mind of the pin and the cottered end of the pin are guarded by cast lugs on the barrel end of the links.

Material

900 Class Pintle Chain are links cast of malleable iron or Promal (Duramal). It is furnished with carbon metal high temperature treated pins and carbon metal case hardened bushings as regular. However, stainless pins and bushings can be provided when specified.

Request a Brochure

and Samples

Request a Brochure

and Samples