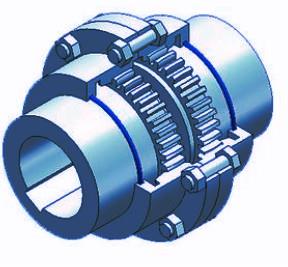

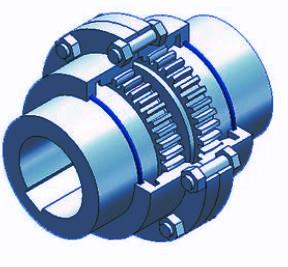

Gear couplings

triple crowned teeth hub is manufactured on a fully automatic hobbing machine with built in crowing attachment which is controlled by hydraulic & electronic systems. Under the misalignment condition of two shafts on the equipment, due to the curvature on teeth flank the contact area is much more and therefore, there is increase in life of coupling.

Gear couplings are power intensive and considered as the king of the coupling types. You would see the gear couplings being adopted for wide range of application in drive technologies. Hence, we love love gear coupling (and I think, you would too!).

Gear Couplings and Universal Joints

Gear couplings and universal joints are used in similar applications. Gear couplings have higher torque densities than universal joints designed to fit a given space, while universal joints induce lower vibrations. The limit on torque density in universal joints is due to the limited cross sections of the cross and yoke.

The gear teeth in a gear coupling have high backlash to allow for angular misalignment. The excess backlash can contribute to vibration.

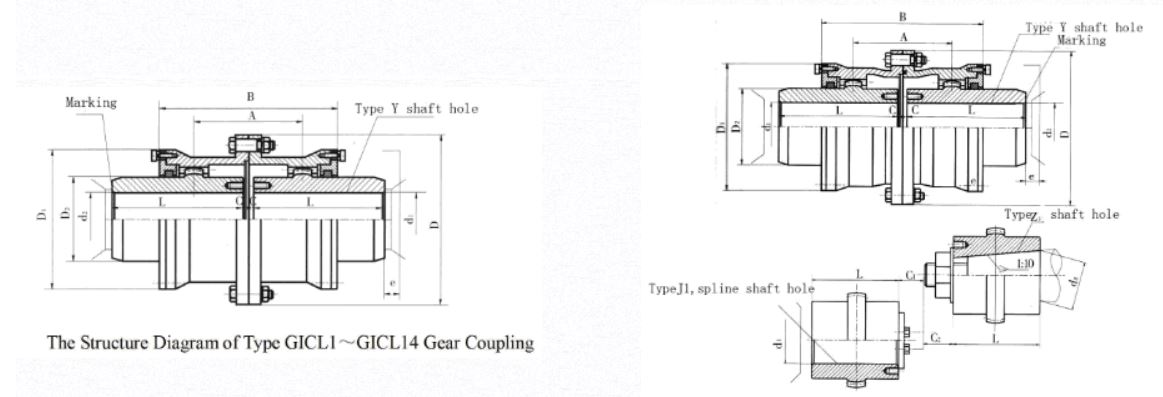

Gear couplings like all other shaft coupling devices perform the basic functions of connecting two shafts to transmit torque and compensate for misalignment. Gear couplings though are the king of the coupling types. While each type of coupling has its own niche, gear couplings are more power intensive, have more modifications, and a wider size, torque, and bore range than all the others. Gear couplings can also perform at extremely high rates of speed. As inferred by the name, gear couplings use the meshing of gear teeth to transmit the torque and to provide for misalignment.

Gear couplings are power intensive. That means more torque transmitted per pound of coupling weight and per cubic inch of space consumed. That allows space and weight for attachments without having the coupling grow to unusable proportions. Power intensity and space savings mean the original equipment manufacturer (OEM) can bury the coupling in small out of the way places. When the OEM does that, it can be done with the confidence that the coupling will not fail. The gear coupling has more torque capability than the shaft can transmit. The gear coupling eventually wears without a spectacular failure. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design.

More size can be sent to you upon inquire!

Request a Brochure

and Samples

Request a Brochure

and Samples