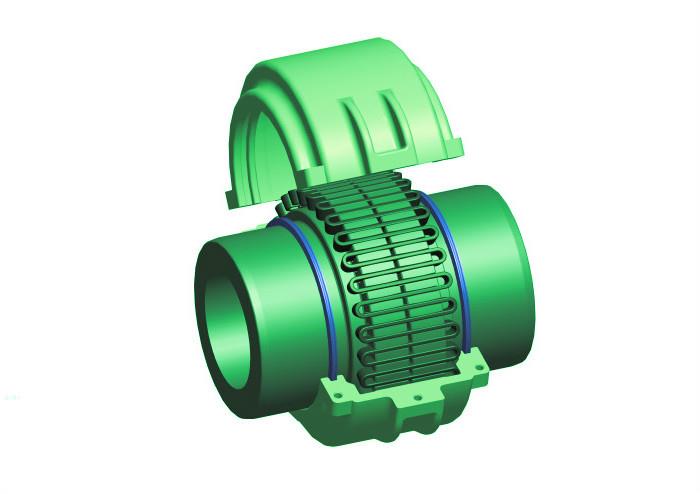

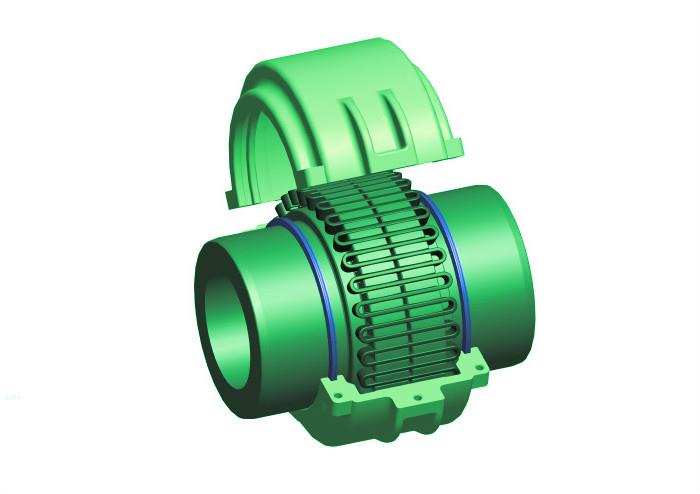

Grid couplings

Grid couplings consist of 2 radially slotted hubs that mesh with a serpentine strip of spring steel the grid provides torsional damping and flexibility of an elastomer but the strength of steel. Grid couplings transmit torque and accommodate angular, parallel and axial misalignment from one hub to the other through the rocking and sliding of a tapered grid in the mating hub slots. The grid cross section is generally tapered for better hub contact and easier assembly. As there is movement between contacting hub and grid metal parts, lubrication is required.

*Superior buffer performance

light load, less contact.

Heavy load, more contact.

Based on actual changeable work load, grid will deform in corresponding degree to fit shaft and damp shock and vibration, protect the host device.

*Long service life

Tapered grids, made of high quality spring steel, undergo strictly heat treatment to perform its best strength and resilience. It greatly outlasts other non - metallic elastic element coupling.

*Swift disassembling and simple maintenance

The grid is the wearing member of the couplings. Simply using common tools can quickly remove the cover and grid, no need to move hub or realign shafts, which can greatly reduce element change-out time. If need to repair or install the core parts of coupling, like hub, just need to release some oil out, then the coupling can be freely moved.

*Professional design,various types

Type G hydraulic grid coupling can provide various types of design for customer’s choice. There are 4 types available: basic type, split type, basic type with sensor, split type with sensor.

*High safety level

Temporary overloads can withstand 2 times the rated torque, which makes the device safe and reliable.

*Low installation requirements

Allow for large installation misalignment. The coupling can work normally under the condition of co - existed parallel, angular and axial misalignment.

*Low operating cost

No need for specialized periodic maintenance when under normal use, as long as fill sufficient amount of grease during installation and replenish grease after long time working. As grease can reduce the transmission noise.

Request a Brochure

and Samples

Request a Brochure

and Samples