nylon gear coupling

Type:

gear

Product applications:

for the food industry

Installation system:

sleeve

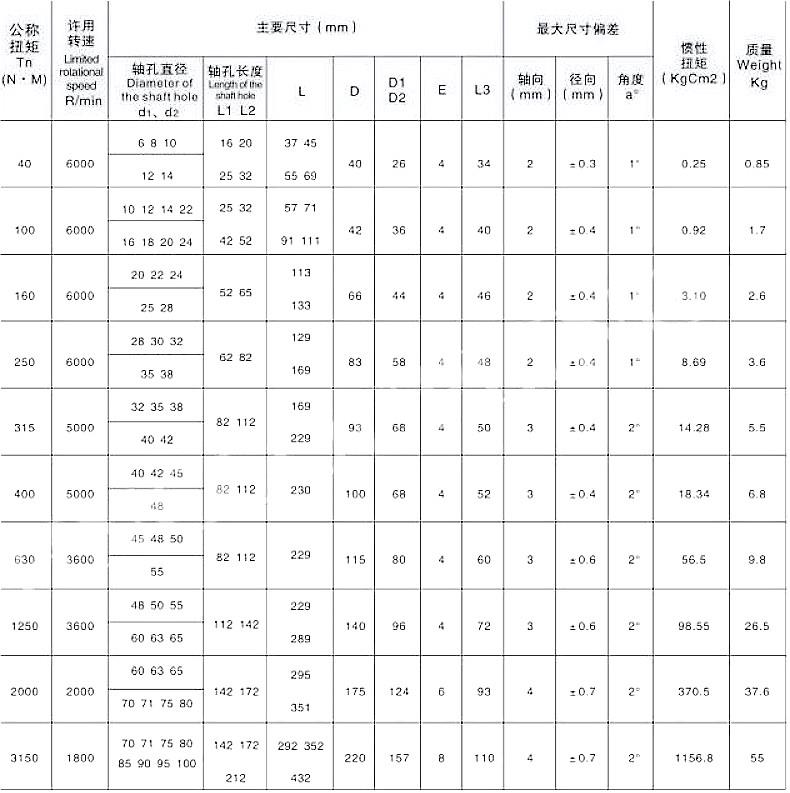

Torque:

Max.: 410 Nm (302.4005 ft.lb)

Min.: 11 Nm (8.1132 ft.lb)

Rotational speed:

Max.: 14,000 rpm (87,964.59 rad.min-1)

Min.: 4,000 rpm (25,132.74 rad.min-1)

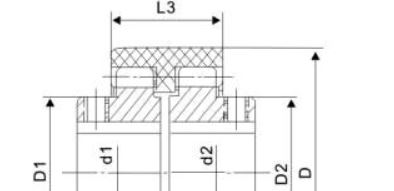

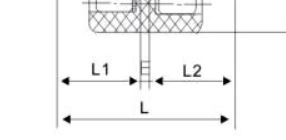

Gear couplings are torsionally rigid and consist of hubs with multi crowned teeth at flank, tip and chamfering on teeth, gaskets, sleeve and O-rings. The hubs attach to the machinery shafts, and sleeves span the gap from one hub to the next. They are available in two designs – completely flexible and flexible/rigid.

The hub is the heart of any gear coupling. Hence manufacturers take great care to impart a superior design and mostly manufacture the hub on CNC machine for precision. Together with the tooth profile of the hub, these aspects enable the gear coupling to function well under all operating conditions with increased reliability and long life.

The tooth flanks and outer diameter of the external gear are crowned to allow for angular displacement between the two gears. The multi crowned teeth reduce the alignment adjustment and improve the load carrying capacity of the teeth. The backlash between the teeth is minimal due to multi-crown tooth design.

A completely flexible coupling comprises two hubs with an external gear and two outer sleeves with an internal gear. It’s a universal coupling for all sorts of applications and accommodates all possible misalignment (angular, radial and combined) as well as large axial moments.

Request a Brochure

and Samples

Request a Brochure

and Samples