Steel Internal Gears -ring gear

Internal spur gears, also know as ring gears, have the same standards as an external spur gear except that the teeth are cut into the inside diameter while the outside is kept smooth. Internal gears can provide a compact solution that delivers large speed reductions and reduced sliding wear action and can be applied in a wide range of equipments & applications. Internal gears are widely used in light duty applications. When it's necessary to have two parallel shafts rotate in the same direction, internal gears eliminate the need for an idler gear.

We have famous customer all over world for ring gear like: Fairfield in USA, Carraro in Italy, Itafran in Fracne etc.....From size 0.5 to 10 M. dia. from 50mm till 2000mm.

More size and bigger gears please send us inquire with details!

Internal Gear drives may be operated with the gear in a fixed position and the pinion rotating along the pitch line, or the gear may be free to rotate with the pinion rotating in a fixed position.

When mating pinions are too close in size to the gear, interference may result. Therefore, the difference in teeth of the pinion to the gear should not be less than 15.

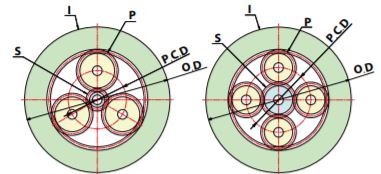

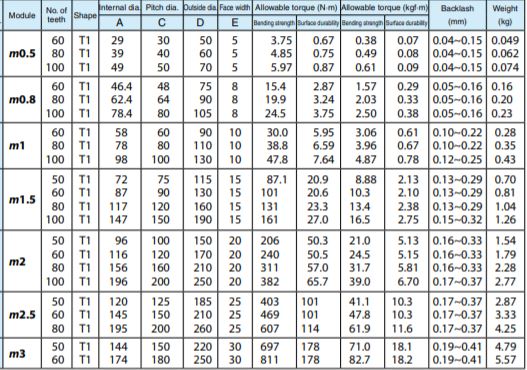

① The backlash values shown in the table are the theoretical values for the normal direction for the internal ring in mesh with a 30 tooth SS spur gear.

② The allowable torque shown in the table are the calculated values according to the assumed usage conditions.

③ Please check for the involute interference, trochoid interference and trimming interference prior to internal gears.

internal ring gears

We can custom manufacture internal gears from a variety of materials that include: steel, stainless steel, heat treated steel, sintered steel, tool steel, ductile iron, gray iron, brass, bronze, copper, cast iron, aluminium, plastic & phenolic. Services include precision blanking, sawing, milling, drilling, tapping, broaching & finishing.

Applications of Internal Gears

Rollers

Electric Screwdrivers

Pumps

Positioning Equipment

Automotives

Bicycle components

Internal Spur Gears

These internal spurs have a cylindrical pitch surface and teeth which are parallel to the axis. However, the internal spur gear teeth are formed on the inner surface of a cylinder. Also, the precision engineered mating component will be an external spur gearing. The teeth are machined during the shaping production step.

A special feature of spur and helical gears is their capability of being made in an internal form, in which an Internal Gear mates with an ordinary external gear. This offers considerable versatility in the design of planetary gear trains and miscellaneous instrument packages. Advantages of an internal gear are the following:

1) Well suited to compact design since the center distance is less than for external gears.

2) A high contact ratio is possible.

3) Good surface endurance due to a convex profile surface working against a concave surface.

Request a Brochure

and Samples

Request a Brochure

and Samples