Worm Gears

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm gear (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm wheel. The terminology is often confused by imprecise use of the term worm...

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm gear (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm wheel. The terminology is often confused by imprecise use of the term worm gear to refer to the worm, the worm gear, or the worm drive as a unit.

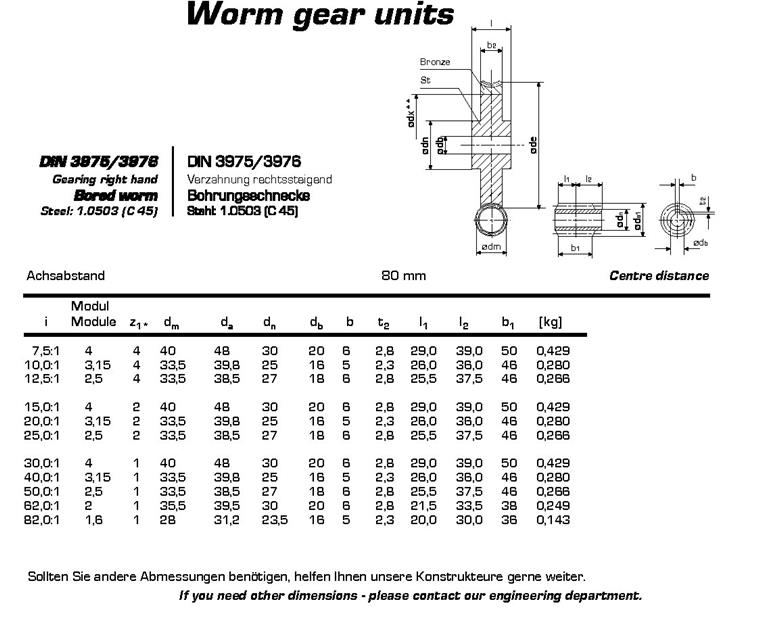

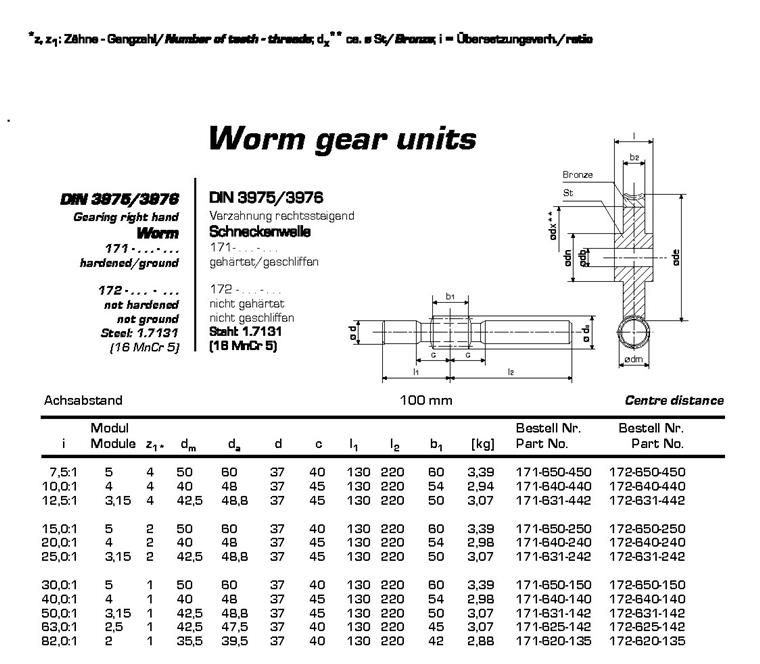

Like other gear arrangements, a worm drive can reduce rotational speed or transmit higher torque. A worm is an example of a screw, one of the six simple machines.

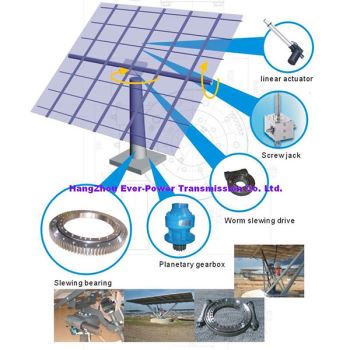

One of the major advantages of worm gear drive units are that they can transfer motion in 90 degrees.

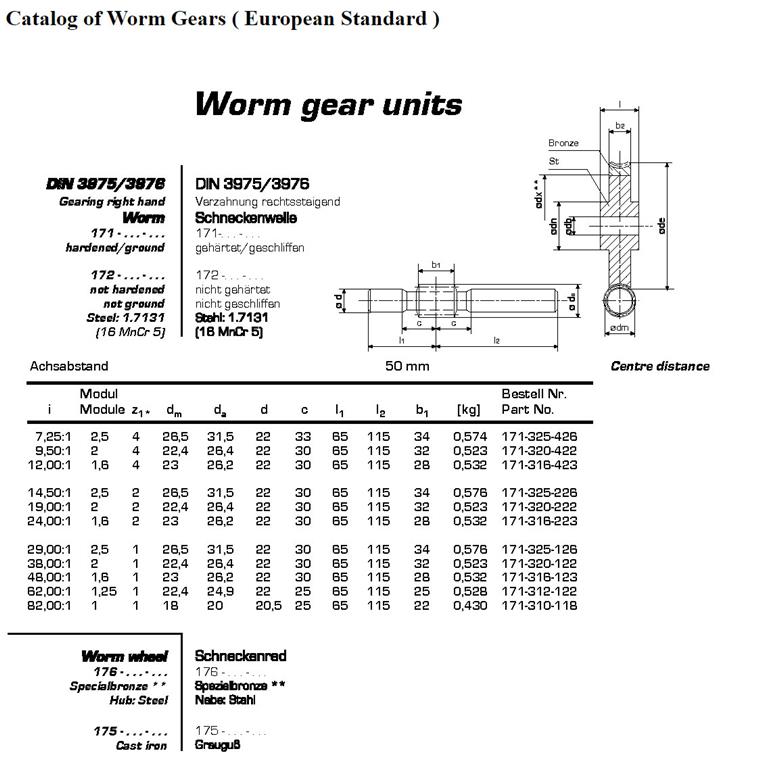

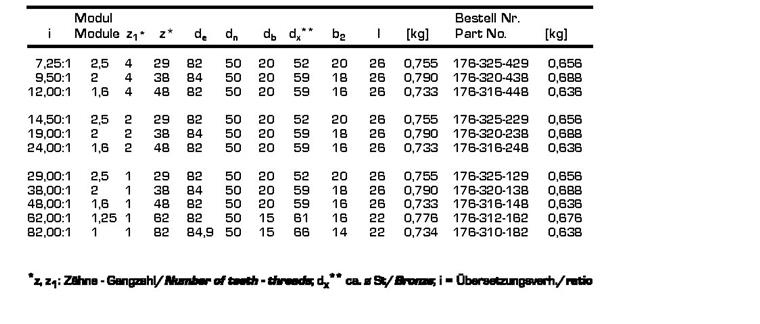

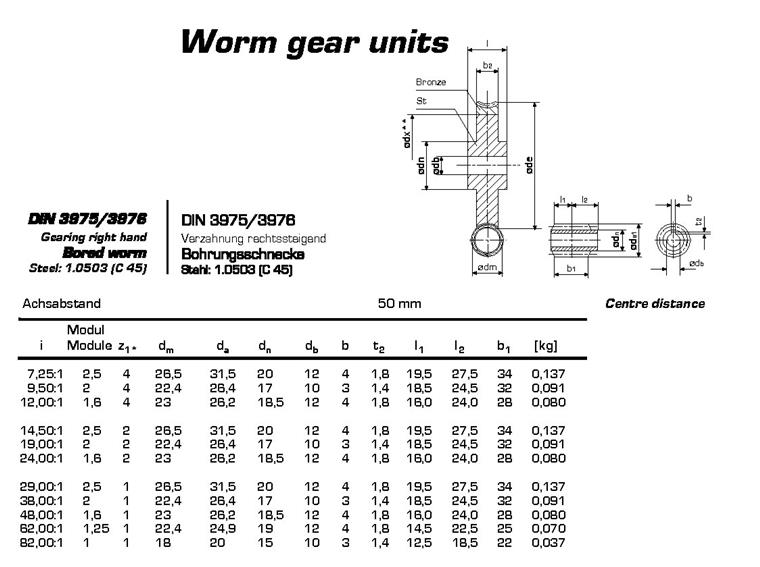

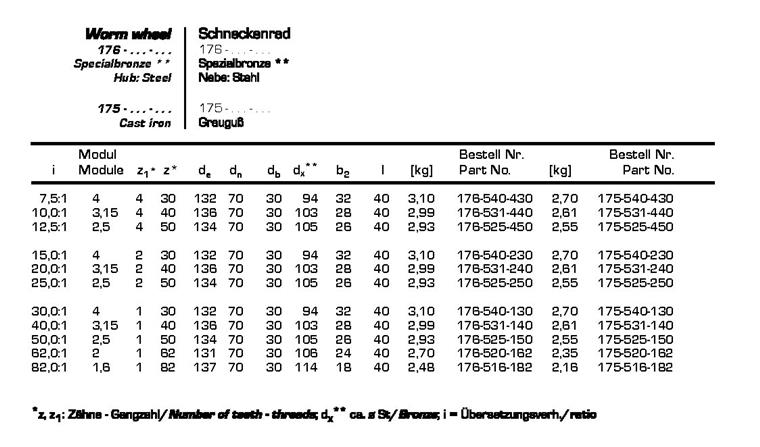

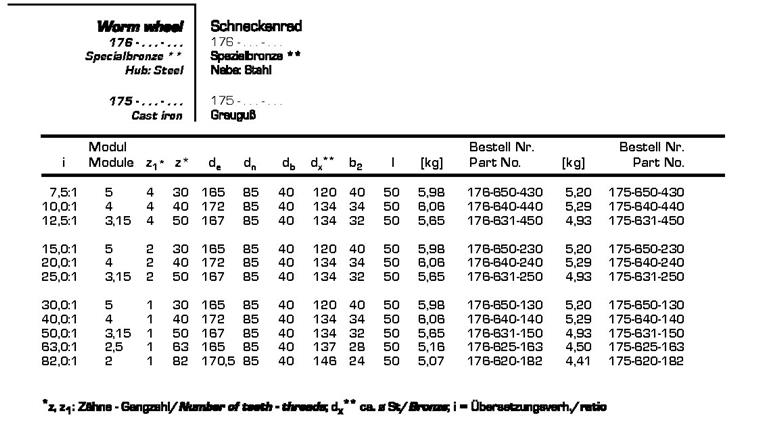

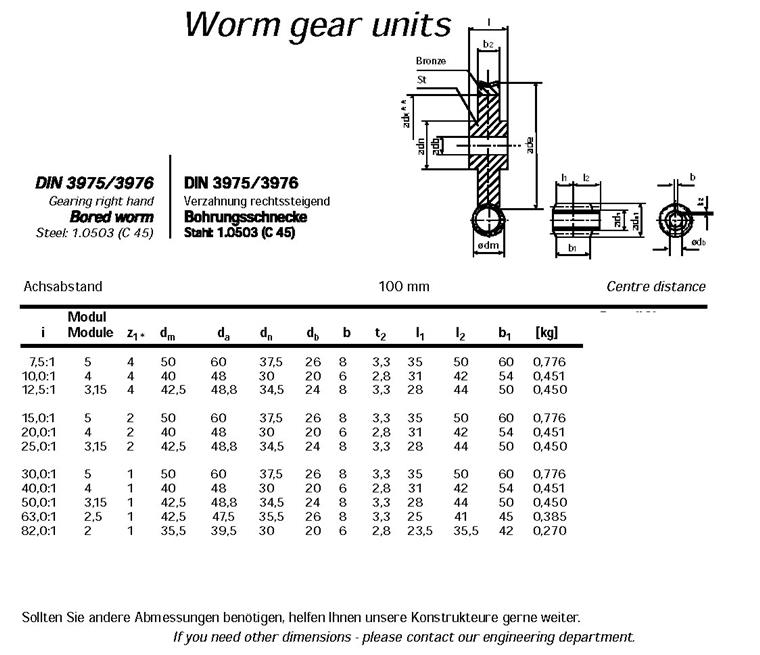

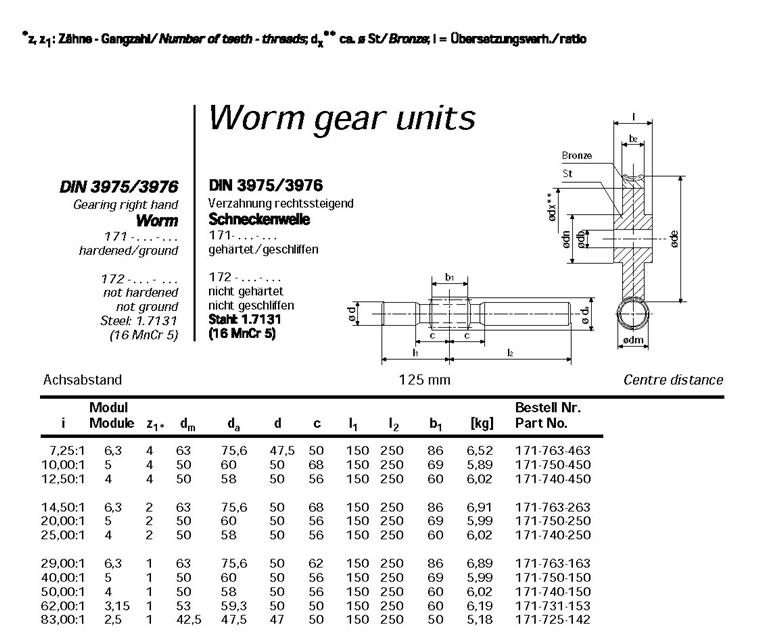

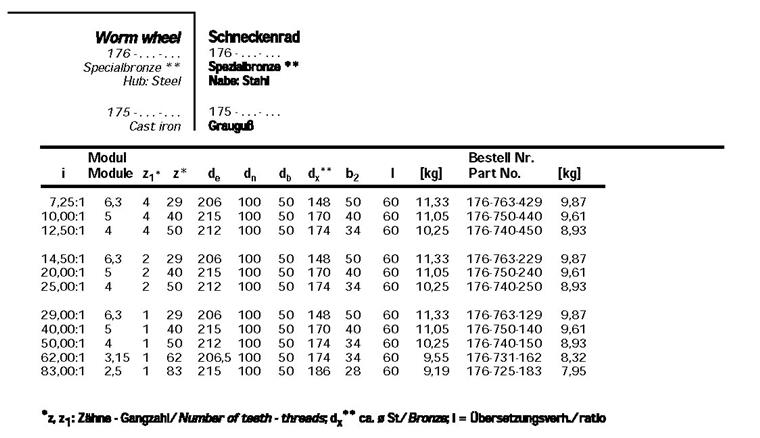

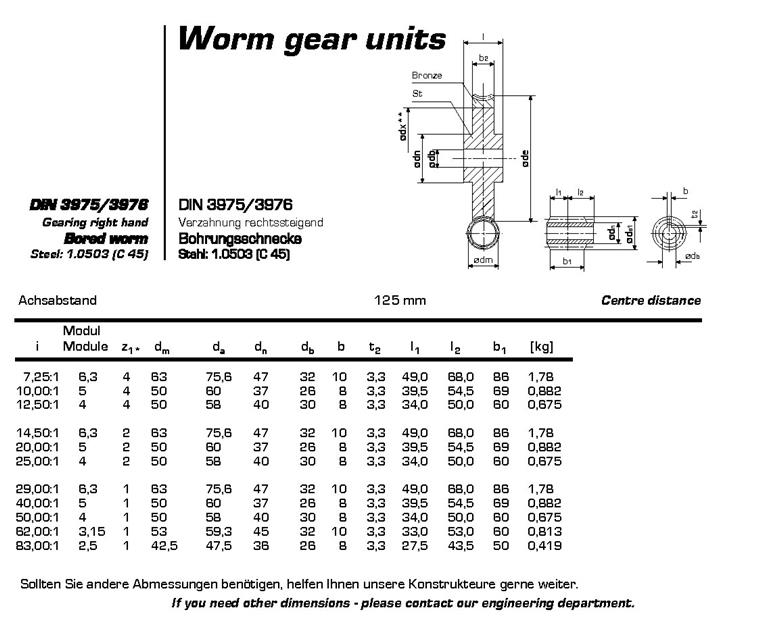

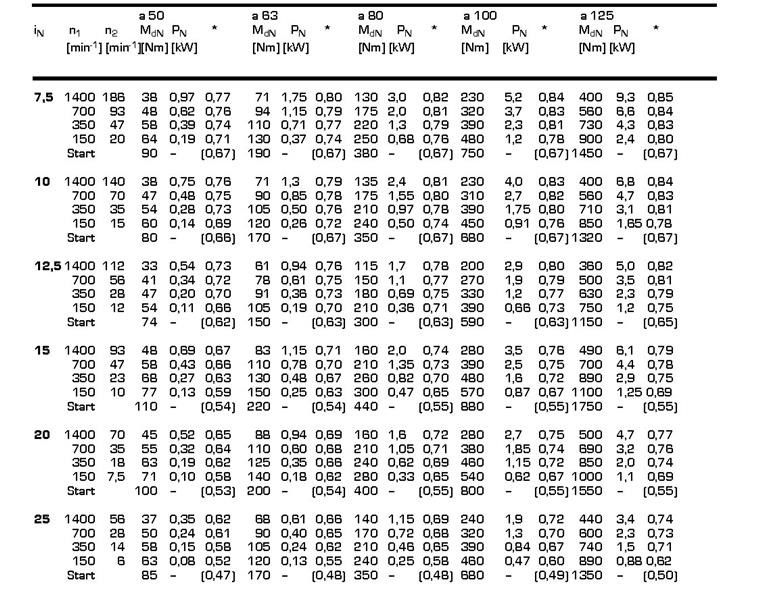

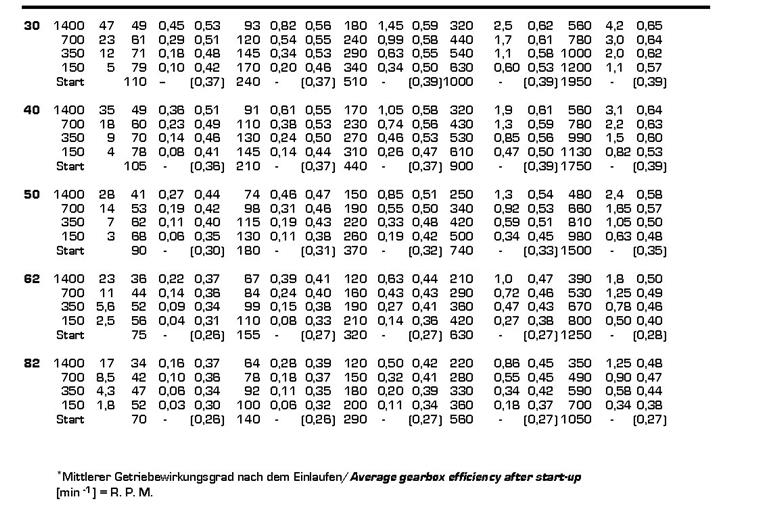

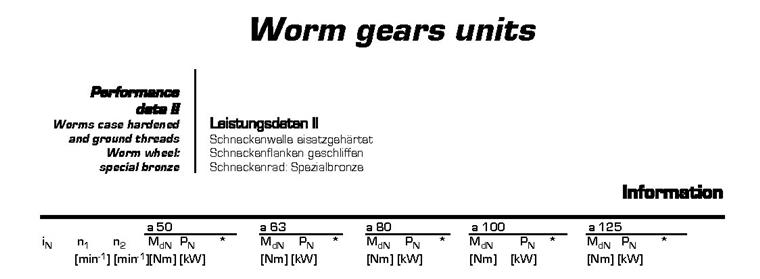

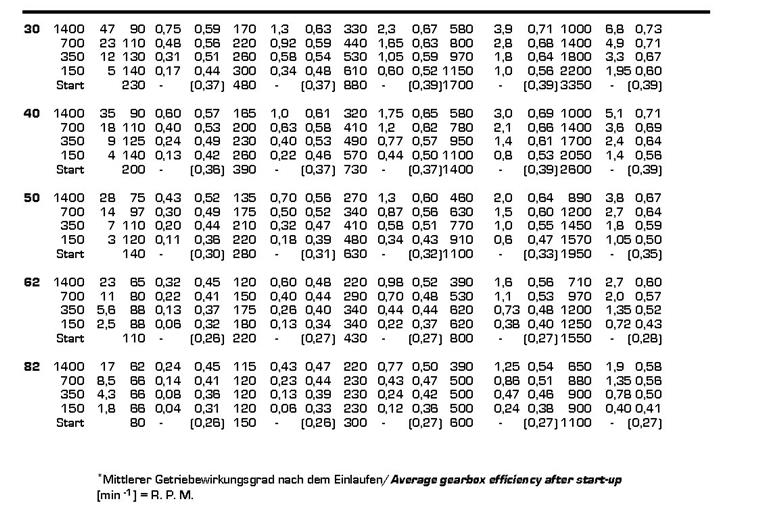

Worm gears are usually used when large speed reductions are needed. The reduction ratio is determined by the number of starts of the worm and number of teeth on the worm gear. But worm gears have sliding contact which is quiet but tends to produce heat and have relatively low transmission efficiency.

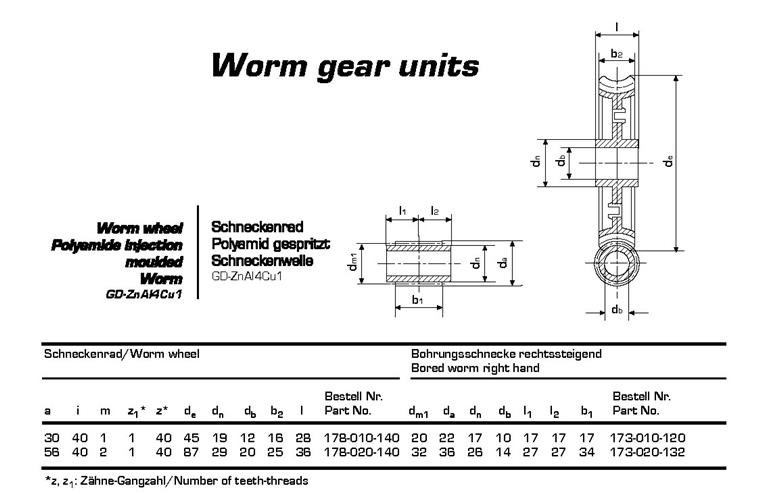

As for the materials for production, in general, worm is made of hard metal while the worm gear is made from relatively soft metal such as aluminum bronze. This is because the number of teeth on the worm gear is relatively high compared to worm with its number of starts being usually 1 to 4, by reducing the worm gear hardness, the friction on the worm teeth is reduced. Another characteristic of worm manufacturing is the need of specialized machine for gear cutting and tooth grinding of worms. The worm gear, on the other hand, may be made with the hobbing machine used for spur gears. But because of the different tooth shape, it is not possible to cut several gears at once by stacking the gear blanks as can be done with spur gears.

The applications for worm gears include gear boxes, fishing pole reels, guitar string tuning pegs, and where a delicate speed adjustment by utilizing a large speed reduction is needed. While you can rotate the worm gear by worm, it is usually not possible to rotate worm by using the worm gear. This is called the self locking feature. The self locking feature cannot always be assured and a separate method is recommended for true positive reverse prevention.

Also there exists duplex worm gear type. When using these, it is possible to adjust backlash, as when the teeth wear necessitates backlash adjustment, without requiring a change in the center distance. There are not too many manufacturers who can produce this type of worm.

The worm gear is more commonly called worm wheel in Japan.

FAQ:

1.CAN YOU DO CUSTOMIZED PRODUCTS?

Yes,we are mainly doing customized products according to the customers’ drawings or samples.

2.HOW MANY EMPLOYEES OF YOUR COMANY?WHAT ABOUT THE TECHNICISTS?

We now have more than 650 employees, including 10 engineers and 50 technicians.

3.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea,because we are in Ningbo,and we are only 35 kilometers away from the Ningbo Port,it is very convenient and efficient to ship goods to any other countries.Of course,if your goods are very urgent,the Ningbo Airport and Shanghai Airport are also very nearby.

Request a Brochure

and Samples

Request a Brochure

and Samples