ANTI BACKLASH SPUR GEARS

Backlash – A “play” between gears

Backlash, sometimes called “play” is a clearance or lost motion in a mechanism caused by gaps between the parts, that is necessary for gearing to function properly. Still, most machine designers think backlash is not desirable as it disturbs their ideal design. However, proper backlash is necessary to prevent damage to the gears caused by a lack of lubrication. In addition, as every gear has deviations, noise and oscillation happen when the gears rotate. Backlash is necessary to reduce noise and oscillation caused by gear deviations, as it helps absorb some of such deviations.

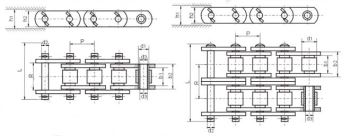

On the other hand, demands for zero-backlash mechanisms still exist. To meet such demands, we released our Standardized Anti-backlash spur gears, which although they cannot remove the backlash completely, can greatly minimize it. Our Anti-backlash spur gears adopt a time-honored mechanism that has built-in springs between gear A and B that pull each other in order to pinch the mating gear like a scissor. When rotated, the direction of the gear is reversible since the springs of the Anti-backlash spur gear can continue to maintain suitable torque by pinching the mating gear. If interference occurs due to gear quality, the Anti-backlash spur gear can help absorb the interference by stretching the spring mechanism between gear A and B while engaged with the mating gear.

Material M | Module m |

Number of Teeth z | Reference Diameter d | Tip Diameter da | Type |

Number of Springs |

Face Width b |

Bore Diameter dd(H8) | Hub Diameter dh | Hub Projection lh |

Overall Length l | Set Screw | |||

M | ls | ||||||||||||||

AL | 0.5 | 60 | f | 30 | f | 31 | BS | 1 | 8 | f 8 | f 16 | 8 | 16 | M4 | 4 |

AL | 0.5 | 70 | f | 35 | f | 36 | BS | 1 | 8 | f 8 | f 16 | 8 | 16 | M4 | 4 |

AL | 0.5 | 80 | f | 40 | f | 41 | BS | 1 | 8 | f 8 | f 20 | 8 | 16 | M4 | 4 |

AL | 0.5 | 90 | f | 45 | f | 46 | BS | 1 | 8 | f 10 | f 20 | 8 | 16 | M4 | 4 |

AL | 0.5 | 100 | f | 50 | f | 51 | BS | 1 | 8 | f 10 | f 20 | 8 | 16 | M4 | 4 |

AL | 0.5 | 120 | f | 60 | f | 61 | BS | 1 | 8 | f 10 | f 20 | 8 | 16 | M4 | 4 |

AL | 0.8 | 50 | f | 40 | f | 41.6 | BS | 1 | 8 | f 10 | f 20 | 10 | 18 | M5 | 5 |

AL | 0.8 | 60 | f | 48 | f | 49.6 | BS | 1 | 8 | f 10 | f 20 | 10 | 18 | M5 | 5 |

AL | 0.8 | 70 | f | 56 | f | 57.6 | BS | 1 | 8 | f 10 | f 20 | 10 | 18 | M5 | 5 |

S | 0.8 | 80 | f | 64 | f | 65.6 | BW | 2 | 8 | f 10(H7) | f 20 | 10 | 18 | M5 | 5 |

S | 0.8 | 90 | f | 72 | f | 73.6 | BW | 2 | 8 | f 10(H7) | f 20 | 10 | 18 | M5 | 5 |

S | 0.8 | 100 | f | 80 | f | 81.6 | BW | 2 | 8 | f 10(H7) | f 24 | 10 | 18 | M5 | 5 |

S | 0.8 | 120 | f | 96 | f | 97.6 | BW | 2 | 8 | f 10(H7) | f 24 | 10 | 18 | M5 | 5 |

AL | 1.0 | 50 | f | 50 | f | 52 | BS | 1 | 10 | f 10 | f 20 | 10 | 20 | M6 | 5 |

AL | 1.0 | 60 | f | 60 | f | 62 | BS | 1 | 10 | f 10 | f 20 | 10 | 20 | M6 | 5 |

S | 1.0 | 70 | f | 70 | f | 72 | BW | 2 | 10 | f 12(H7) | f 24 | 10 | 20 | M6 | 5 |

S | 1.0 | 80 | f | 80 | f | 82 | BW | 2 | 10 | f 12(H7) | f 24 | 10 | 20 | M6 | 5 |

S | 1.0 | 90 | f | 90 | f | 92 | BW | 3 | 10 | f 12(H7) | f 24 | 10 | 20 | M6 | 5 |

S | 1.0 | 100 | f 100 | f 102 | BW | 3 | 10 | f 12(H7) | f 30 | 10 | 20 | M6 | 5 | ||

S | 1.0 | 120 | f 120 | f 122 | BW | 3 | 10 | f 12(H7) | f 30 | 10 | 20 | M6 | 5 | ||

Request a Brochure

and Samples

Request a Brochure

and Samples