CHM - WORM GEARED MOTORS AND WORM GEAR UNITS

CHM - WORM GEARED MOTORS AND WORM GEAR UNITS

CHM - WORM GEARED MOTORS AND WORM GEAR UNITS

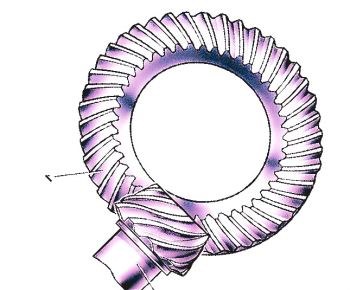

The worm gears made by EP are square and are considerably versatile for mounting. The machining of the components, carried out using numeric control machines, guarantees maximum precision for the restricted tolerances, producing a product that will remain reliable over time. The groups are constructed with aluminium casings from sizes 025 to 090, while the sizes 110, 130 and 150 are made from cast iron. All of the bodies are painted with RAL 9022 aluminium colour to protect the parts from aging and to give better protection against microblowholes that may be present in the aluminium. The gears are supplied with at least one filling plug that is also used during testing to check for possible leaks. A connection flange allows two gears to be combined in order to obtain high gear ratios. Four sizes of CHPC pre-stage gears are available to pair with the gears; these are also constructed in aluminium and are painted like the worm gears

Gears that are supplied with mounting flanges must be assembled with motors whose shaft and flange tolerances correspond to a “normal class” of quality in order to avoid vibration and forcing of the input bearing. Motors supplied by Chiaravalli Group S.p.A. guarantee that this requirement is fulfilled. For ease of consultation, the correspondence of the size of the B5 and B14 motor with the sizes of the shaft and the motor connection flange are shown in the following table. Remember that, as the motor connection flanges are separate from the body it is also possible to have a shaft / flange combination that does not correspond to the table, e.g. 19/140, thereby offering adaptability for other non-unified models such as the brushless or direct current types.

Request a Brochure

and Samples

Request a Brochure

and Samples