CH WORM GEARED MOTORS AND WORM GEAR UNITS TYPE CHR 03 CHR 04 CHR 05 CHR 06 CHR 07 CHR 08 CHRE 03 CHRE 04 CHRE 05 CHRE 06 CHRE 07 CHRE 08

CH WORM GEARED MOTORS AND WORM GEAR UNITS TYPE CHR 03 CHR 04 CHR 05 CHR 06 CHR 07 CHR 08 CHRE 03 CHRE 04 CHRE 05 CHRE 06 CHRE 07 CHRE 08

CH WORM GEARED MOTORS AND WORM GEAR UNITS

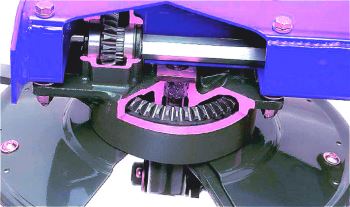

Starting from these considerations, we have a gearbox with a motor mounting flange that is separable from the housing which incorporate the oil seal; in this way we avoid any risk of damaging the oil seal in case of replacement of the input flange and the O-Ring can be eliminated. All the aside covers, swinging and with feet, have O-Rings instead of traditional flat gaskets. The sizes 03-04-05 allow the rotation of the feet without disassembling them; furthermore the versions with swinging aside covers allow the lateral flanges to be fitted on both sides with simple fixing screws. The worm screw has a ZI involute profile: with this worm-wheel coupling we shall get a better performance with a temperature reduction. The gearboxes and motors are painted with RAL 9022 aluminium colour epoxy powder to protect the parts from oxidation and against micro-blowholes that can come during the pressure of die-castings. The CHPC pre-stage gears (already present in the catalogue of CHM) can also be mounted with this range, obtaining a gear ratio up to 1:300. For bigger reductions is possible to have two gears together using an appropriate kit

TYPE

CHR 03

CHR 04

CHR 05

CHR 06

CHR 07

CHR 08

CHRE 03

CHRE 04

CHRE 05

CHRE 06

CHRE 07

CHRE 08

Request a Brochure

and Samples

Request a Brochure

and Samples