Ever-Power Brushless DC Motors

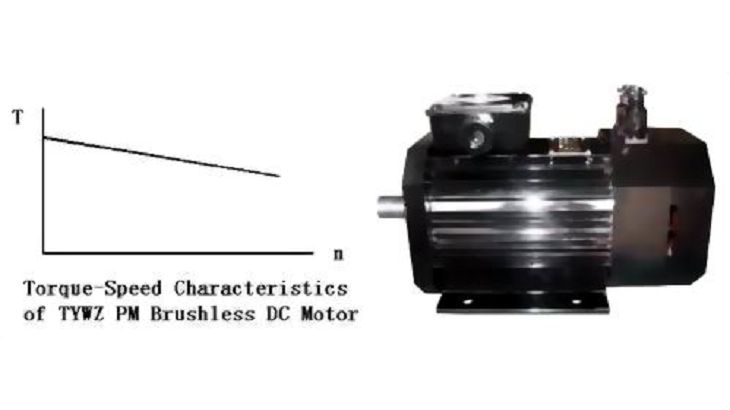

TYWZ DC Brushless Motor takes rare earth PM material as its rotor material, replace carbon brush commutator with location sensor, realize electronic inverting with electronic control circuit. It has retained the advantage owned by the traditional DC motor, at the same time overcome the disadvantages such as complicated structure of carbon brush and slip-ring, high fault rates.

Ever-Power Brushless DC motors

TYWZ DC Brushless Motor takes rare earth PM material as its rotor material, replace carbon brush commutator with location sensor, realize electronic inverting with electronic control circuit. It has retained the advantage owned by the traditional DC motor, at the same time overcome the disadvantages such as complicated structure of carbon brush and slip-ring, high fault rates.

● Excellent torque performance, high start torque;

● High precision of speed control, wide speed scope;

● Little rotor Rotate Inertia, rapid response speed;

● Small size, light weight, large power ratio( the ration of power and size);

● Good brake performance;

● High efficiency, no rubbing mechanical wastage between exciting power and carbon brush, slip ring, an energy saving product;

● Simple structure, high reliability, good stability, simple to repair and maintain; lower noise,more smooth running, more longer life;

● No radio disturb, no electrical spark produced by rubbing of electrical brush, especially suitable for the application fields such as the explosive dangerous area, the bad working environment,frequently fast start etc;

| TYPE | VOLT. (V) | POWER (kW) | SPEED RPM | CURR. (A) | Effici. η(%) | COSθ | Protec. Grade | weight(kg) |

| TYWZ-18-63 | DC220 | 0.18 | 3000 | 1.1 | 90 | 0.91 | IP54 or IP55

| 5 |

| TYWZ-50-63 | DC24 | 0.5 | 3000 | 25 | 90 | 0.88 | 5 | |

| TYWZ-75-71 | AC220 | 0.75 | 4000 | 2.6 | 89 | 0.86 | 8 | |

TYWZ-250-80 | AC220 | 2.5 | 3000 | 7.5 | 93 | 0.93 | 12 |

Note: Some new specifications are not shown in the table. Prompt design according to customer’s requirement is available.

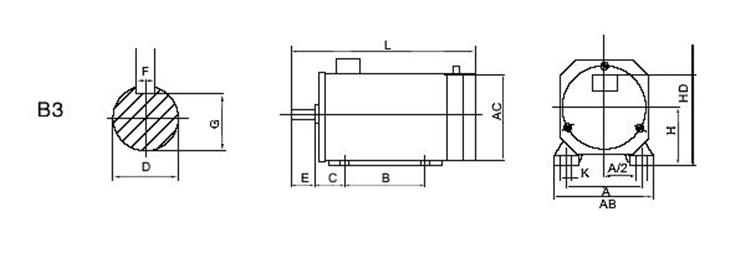

Mounting base | Poles | Mounting Dimension | Overall dimension | ||||||||||||

A | A/2 | B | C | D | E | F | G | H | K | AB | AC | HD | L | ||

71 | 4、6 | 112 | 56 | 90 | 50 | 19 | 40 | 6 | 15.5 | 71 | 7 | 150 | 130?/FONT>139 | 176 | 310 |

80 | 4、6、8 | 125 | 62.5 | 100 | 56 | 24 | 50 | 8 | 20 | 80 | 10 | 165 | 148?/FONT>140 | 196 | ※395 |

112 | 4、6、8 | 190 | 95 | 140 | 89 | 38 | 80 | 10 | 33 | 112 | 12 | 230 | 187?87 | 300 | 460 |

132 | 4、6、8 | 216 | 108 | 178 | 108 | 42 | 110 | 12 | 37 | 132 | 12 | 270 | 224?/FONT>224 | 350 | 610 |

160 | 4、6、8 | 254 | 127 | 254 | 121 | 48 | 110 | 14 | 42.5 | 160 | 15 | 320 | 274?74 | 420 | 680 |

180 | 4、6、8 | 279 | 140 | 279 | 133 | 55 | 110 | 16 | 49 | 180 | 19 | 355 | 340?40 | 460 | 750 |

Note: ※is the dimension of motor less then 4kw

The dimension L of 4kw motor is approximately 470.

Dimension marked italic will be little changed according to motor power.

Some new special specifications are not shown in the table. They are smaller.

Prompt design according to customer’s requirement is available.

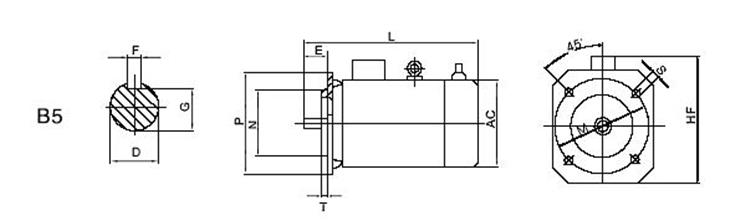

| Frame size | Poles | Mounting Dimension | Overall dimension | |||||||||||

| D | E | F | G | M | N | P | S | T | Flange holes | AC | HF | L | ||

| 71 | 4、6 | 19 | 40 | 6 | 15.5 | 130 | 110 | 140?40 | 10 | 3.5 | 4 | 130?39 | 165 | 350 |

| 80 | 4、6、8 | 24 | 50 | 8 | 20 | 165 | 130 | 148?48 | 12 | 3.5 | 4 | 148?40 | 176 | ※395 |

| 112 | 4、6、8 | 38 | 80 | 10 | 33 | 215 | 180 | 240?40 | 15 | 4 | 4 | 187?87 | 245 | 390 |

| 132 | 4、6、8 | 42 | 110 | 12 | 37 | 265 | 230 | 290?90 | 15 | 4 | 4 | 224?24 | 290 | 630 |

| 160 | 4、6、8 | 48 | 110 | 14 | 42.5 | 300 | 250 | 316?16 | 19 | 5 | 4 | 278?78 | 340 | 680 |

| 180 | 4、6、8 | 55 | 110 | 16 | 49 | 300 | 250 | 350?50 | 19 | 5 | 4 | 340?40 | 400 | 750 |

Note:※is the dimension of motor less then 4kw

The dimension L of 4kw motor is approximately 470.

Dimension marked italic will be little changed according to motor power.

Some new special specifications are not shown in the table. They are smaller.

Prompt design according to customer’s requirement is available .

Request a Brochure

and Samples

Request a Brochure

and Samples