Plastic Spur Gears With Stainless Steel Core

Plastic Spur Gears with Stainless Steel Core

Plastic Spur Gears with Stainless Steel Core

Materials

Type | [ M ]Material | [ A ]Accessories | |

Gears | Metal Hub | ||

HZPTM | MC Nylon | - | Set Screw |

HZPTMS | 1045 Carbon Steel | ||

HZPTMT | 304 Stainless Steel | Set Screw (304 Stainless Steel) | |

HZPTP | Polyacetal | - | Set Screw (4137 Alloy Steel, |

HZPTPS | 1045 Carbon Steel | ||

HZPTPT | 304 Stainless Steel | Set Screw (304 Stainless Steel) | |

[ ! ]Set Screw is not included in products with Gear Shape A.

Caution on Product Characteristics] ① Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), including bore size (H8 when produced),

tooth diameter, and backlash. Please see the section “Design of Plastic Gears” in separate technical reference book.

② The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please ask for more details.

③ When the core O.D is the same as the hub diameter, you may see some serration on the hub. There is no effect on the strength of the gear.

④ Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears.

⑤ The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh

Specifications

Part Number | - | Number of Teeth | - | B | - | Gear | - | P |

HZPTM1.0 | - | 20 | - | 10 | - | A | - | 8 |

[ ! ]When gear shape is not specified, Module 1.0 with 18 or more number of teeth and Module 1.5, 2.0, 2.5, 3.0 will be Shape B.

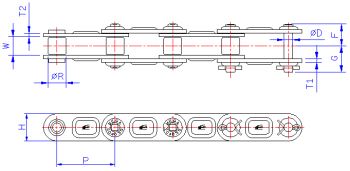

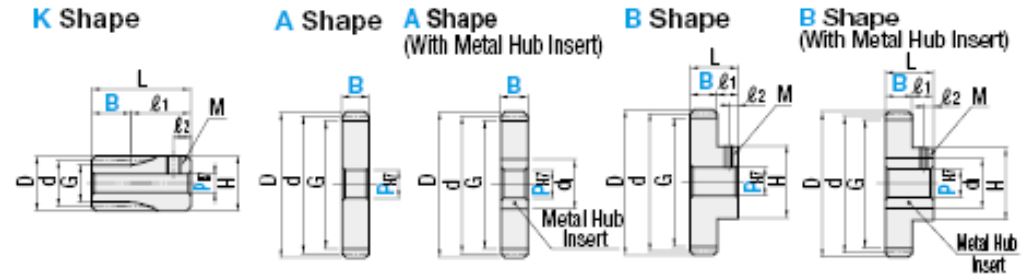

Part Number | Number of Teeth | B | Gear Shape | Shaft Bore Dia. PH7 | d Reference Dia. | D Tip Dia. | G Root Dia. | H | L | ℓ1 | ℓ2 | M (Coarse) | d1 | *1. Allowable Transmission Force (N·m) Bending Strength | |||

Type | Module | W/o Metal Hub Insert | With Metal Hub Insert | MC Nylon | Polyacetal | ||||||||||||

HZPTM | 0.5 | *15 | 8 | K | 3~5 | - | 7.5 | 8.5 | 6.25 | 9 | 18 | 10 | 3 | M3 | - | 0.08 | 0.33 |

*16 | 8 | 9 | 6.75 | 0.09 | 0.36 | ||||||||||||

*18 | 3~7 | 9 | 10 | 7.75 | 10 | 0.11 | 0.42 | ||||||||||

*20 | 10 | 11 | 8.75 | 11 | 0.12 | 0.49 | |||||||||||

*20 | 3 | B | 3~5 | 10 | 11 | 8.75 | 8.5 | 8 | 5 | 2.5 | 0.05 | 0.18 | |||||

*24 | 3~7 | 12 | 13 | 10.75 | 10 | 0.06 | 0.23 | ||||||||||

*25 | 12.5 | 13.5 | 11.25 | 0.06 | 0.24 | ||||||||||||

*28 | 14 | 15 | 12.75 | 0.07 | 0.28 | ||||||||||||

*30 | 15 | 16 | 13.75 | 0.08 | 0.31 | ||||||||||||

*32 | 16 | 17 | 14.75 | 0.08 | 0.33 | ||||||||||||

*36 | 18 | 19 | 16.75 | 0.10 | 0.39 | ||||||||||||

*40 | 2 | 20 | 21 | 18.75 | 0.11 | 0.44 | |||||||||||

*45 | 22.5 | 23.5 | 21.25 | 0.13 | 0.51 | ||||||||||||

*48 | 24 | 25 | 22.75 | 0.14 | 0.55 | ||||||||||||

*50 | 25 | 26 | 23.75 | 0.15 | 0.58 | ||||||||||||

*56 | 3 | 28 | 29 | 26.75 | 0.17 | 0.67 | |||||||||||

*60 | 30 | 31 | 28.75 | 0.18 | 0.73 | ||||||||||||

*64 | 32 | 33 | 30.75 | 0.20 | 0.78 | ||||||||||||

*70 | 3~8 | 35 | 36 | 33.75 | 12 | 0.22 | 0.86 | ||||||||||

*72 | 36 | 37 | 34.75 | 0.22 | 0.89 | ||||||||||||

*80 | 40 | 41 | 38.75 | 0.25 | 0.99 | ||||||||||||

*90 | 3~9 | 45 | 46 | 43.75 | 14 | 0.28 | 1.13 | ||||||||||

*100 | 50 | 51 | 48.75 | 0.32 | 1.27 | ||||||||||||

*120 | 60 | 61 | 58.75 | 0.39 | 1.54 | ||||||||||||

0.8 | *12 | 7 | K | 4~7 | - | 9.6 | 11.2 | 7.6 | 11.2 | 20 | 13 | 3 | M3 | - | 0.13 | 0.50 | |

*14 | 4~8 | 11.2 | 12.8 | 9.2 | 12.8 | 0.17 | 0.66 | ||||||||||

*15 | 4~9 | 12 | 13.6 | 10 | 13.6 | 0.18 | 0.73 | ||||||||||

*16 | 5 | B | 4~7 | 12.8 | 14.4 | 10.8 | 10 | 14 | 9 | 0.15 | 0.58 | ||||||

*18 | 14.4 | 16 | 12.4 | 0.17 | 0.67 | ||||||||||||

*20 | 16 | 17.6 | 14 | 0.20 | 0.78 | ||||||||||||

*24 | 5~8 | 19.2 | 20.8 | 17.2 | 12.5 | 0.25 | 0.98 | ||||||||||

*25 | 20 | 21.6 | 18 | 0.26 | 1.04 | ||||||||||||

*28 | 22.4 | 24 | 20.4 | 0.30 | 1.20 | ||||||||||||

*30 | 24 | 25.6 | 22 | 0.33 | 1.30 | ||||||||||||

*32 | 25.6 | 27.2 | 23.6 | 4 | 0.36 | 1.42 | |||||||||||

*36 | 6~9 | 28.8 | 30.4 | 26.8 | 14 | M4 | 0.42 | 1.65 | |||||||||

*40 | 32 | 33.6 | 30 | 0.47 | 1.88 | ||||||||||||

*45 | 36 | 37.6 | 34 | 0.55 | 2.18 | ||||||||||||

*48 | 38.4 | 40 | 36.4 | 0.59 | 2.36 | ||||||||||||

*50 | 40 | 41.6 | 38 | 0.63 | 2.49 | ||||||||||||

*56 | 44.8 | 46.4 | 42.8 | 0.72 | 2.85 | ||||||||||||

*60 | 48 | 49.6 | 46 | 0.78 | 3.11 | ||||||||||||

*64 | 51.2 | 52.8 | 49.2 | 0.84 | 3.33 | ||||||||||||

*70 | 6~11 | 56 | 57.6 | 54 | 16 | 0.92 | 3.66 | ||||||||||

*72 | 57.6 | 59.2 | 55.6 | 0.95 | 3.78 | ||||||||||||

*80 | 64 | 65.6 | 62 | 1.07 | 4.24 | ||||||||||||

*90 | 6~14 | 72 | 73.6 | 70 | 20 | 1.21 | 4.83 | ||||||||||

*100 | 6~16 | 80 | 81.6 | 78 | 24 | 1.37 | 5.43 | ||||||||||

*120 | 6~21 | 96 | 97.6 | 94 | 30 | 1.66 | 6.58 | ||||||||||

1.0 | 15 | 12 | A | 6~10 | 6 | 15 | 17 | 12.5 | - | - | - | - | - | P+4 | 0.49 | 1.71 | |

*16 | K | 8~12 | - | 16 | 18 | 13.5 | 18 | 25 | 13 | 3 | M3 | - | 0.54 | 1.89 | |||

18 | 10 | A | 8~10 | 8 | 18 | 20 | 15.5 | 15 | 20 | 10 | 4 | M4 | P+4 | 0.53 | 1.84 | ||

20 | 8~11 | 20 | 22 | 17.5 | 16 | 0.61 | 2.13 | ||||||||||

22 | 8~12 | 22 | 24 | 19.5 | 18 | 0.69 | 2.41 | ||||||||||

24 | 8~14 | 8, 10 | 24 | 26 | 21.5 | 20 | 0.77 | 2.69 | |||||||||

25 | 25 | 27 | 22.5 | 0.82 | 2.84 | ||||||||||||

26 | 8~15 | 26 | 28 | 23.5 | 22 | 0.86 | 3.00 | ||||||||||

28 | 28 | 30 | 25.5 | 0.94 | 3.28 | ||||||||||||

30 | 10~17 | 10, 12 | 30 | 32 | 27.5 | 25 | 1.03 | 3.56 | |||||||||

32 | 10~18 | 32 | 34 | 29.5 | 26 | 1.11 | 3.87 | ||||||||||

35 | 35 | 37 | 32.5 | 1.25 | 4.34 | ||||||||||||

36 | 10~19 | 10, 12, 15 | 36 | 38 | 33.5 | 28 | 1.30 | 4.51 | |||||||||

40 | 10~21 | 40 | 42 | 37.5 | 30 | 1.48 | 5.15 | ||||||||||

45 | 45 | 47 | 42.5 | 1.71 | 5.95 | ||||||||||||

48 | 48 | 50 | 45.5 | 1.86 | 6.45 | ||||||||||||

50 | 10~24 | 10, 12, 15,20 | 50 | 52 | 47.5 | 35 | 1.96 | 6.80 | |||||||||

55 | 55 | 57 | 52.5 | 2.20 | 7.63 | ||||||||||||

60 | 60 | 62 | 57.5 | 2.44 | 8.49 | ||||||||||||

70 | 10~28 | 70 | 72 | 67.5 | 40 | 2.88 | 10.02 | ||||||||||

75 | 75 | 77 | 72.5 | 3.11 | 10.80 | ||||||||||||

80 | 80 | 82 | 77.5 | 3.33 | 11.59 | ||||||||||||

90 | 90 | 92 | 87.5 | 3.80 | 13.19 | ||||||||||||

100 | 100 | 102 | 97.5 | 4.27 | 14.84 | ||||||||||||

120 | 120 | 122 | 117.5 | 5.18 | 17.99 | ||||||||||||

1.5 | 15 | 15 | A | 8~12 | 8 | 22.5 | 25.5 | 18.75 | 18 | 24 | 9 | 3 | M3 | P+4 | 1.38 | 3.16 | |

16 | 8~14 | 8, 10 | 24 | 27 | 20.25 | 20 | 1.53 | 3.50 | |||||||||

18 | 8~15 | 27 | 30 | 23.25 | 22 | 27 | 12 | 4 | M4 | 1.79 | 4.08 | ||||||

20 | 8~17 | 8, 10, 12 | 30 | 33 | 26.25 | 25 | 2.07 | 4.73 | |||||||||

24 | 8~21 | 8, 10, 12,15 | 36 | 39 | 32.25 | 30 | 2.61 | 5.97 | |||||||||

25 | 8~21 | 37.5 | 40.5 | 33.75 | 2.76 | 6.30 | |||||||||||

26 | 8~22 | 39 | 42 | 35.25 | 32 | 2.91 | 6.65 | ||||||||||

28 | 8~23 | 42 | 45 | 38.25 | 34 | 3.18 | 7.27 | ||||||||||

30 | 8~24 | 8, 10, 12,15, 20 | 45 | 48 | 41.25 | 35 | 3.46 | 7.90 | |||||||||

32 | 8~28 | 48 | 51 | 44.25 | 40 | 3.76 | 8.58 | ||||||||||

35 | 8~28 | 52.5 | 55.5 | 48.75 | 4.22 | 9.63 | |||||||||||

36 | 8~28 | 54 | 57 | 50.25 | 4.38 | 10.00 | |||||||||||

40 | 10~31 | 10, 12, 15,20, 25 | 60 | 63 | 56.25 | 45 | 5.00 | 11.42 | |||||||||

45 | 10~31 | 67.5 | 70.5 | 63.75 | 5.78 | 13.20 | |||||||||||

48 | 10~31 | 72 | 75 | 68.25 | 6.27 | 14.31 | |||||||||||

50 | 10~31 | 75 | 78 | 71.25 | 6.60 | 15.08 | |||||||||||

60 | 10~35 | 90 | 93 | 86.25 | 50 | 8.24 | 18.83 | ||||||||||

70 | 12~35 | 12, 15, 20,25 | 105 | 108 | 101.25 | 9.72 | 22.21 | ||||||||||

80 | 12~38 | 120 | 123 | 116.25 | 55 | 11.25 | 25.70 | ||||||||||

[ NG ]Number of Teeth with *is not With Metal Hub Insert Type.

*1 Allowable Transmission Forces in the table are reference values calculated with prescribed conditions. For conditions >> Click here Module 0.5 with 40~50 teeth are calculated as tooth width 3mm.

Part Number | Number of Teeth | B | Gear Shape | Shaft Bore Dia. PH7 | d Reference Dia. | D Tip Dia. | G Root Dia. | H | L | ℓ1 | ℓ2 | M (Coarse) | d1 | *1. Allowable Transmission Force (N·m) Bending Strength | |||

Type | Module | W/o Metal Hub Insert | With Metal Hub Insert | MC Nylon | Polyacetal | ||||||||||||

HZPTM | 2.0 | *12 | 20 | A | 10~12 | - | 24 | 28 | 19.0 | 18 | 34 | 14 | 4 | M4 | - | 2.25 | 2.45 |

14 | 10~14 | 10 | 28 | 32 | 23.0 | 20 | P+4 | 2.96 | 3.23 | ||||||||

15 | 10~16 | 10, 12 | 30 | 34 | 25.0 | 24 | 3.28 | 3.59 | |||||||||

16 | 10~17 | 10, 12, 15 | 32 | 36 | 27.0 | 25 | 3.63 | 3.97 | |||||||||

18 | 10~21 | 36 | 40 | 31.0 | 30 | 4.24 | 4.63 | ||||||||||

20 | 10~23 | 40 | 44 | 35.0 | 33 | 4.91 | 5.36 | ||||||||||

24 | 10~28 | 10, 12, 15,20 | 48 | 52 | 43.0 | 40 | 6.19 | 6.77 | |||||||||

25 | 50 | 54 | 45.0 | 6.54 | 7.15 | ||||||||||||

28 | 10~31 | 10,12, 15,20, 25 | 56 | 60 | 51.0 | 45 | 7.54 | 8.24 | |||||||||

30 | 10~33 | 60 | 64 | 55.0 | 48 | 8.20 | 8.96 | ||||||||||

32 | 12~35 | 12, 15, 20, | 64 | 68 | 59.0 | 50 | 8.91 | 9.73 | |||||||||

35 | 12~35 | 70 | 74 | 65.0 | 9.99 | 10.92 | |||||||||||

36 | 12~35 | 72 | 76 | 67.0 | 10.38 | 11.34 | |||||||||||

40 | 12~42 | 80 | 84 | 75.0 | 60 | 11.86 | 12.95 | ||||||||||

45 | 90 | 94 | 85.0 | 13.70 | 14.97 | ||||||||||||

48 | 96 | 100 | 91.0 | 14.85 | 16.23 | ||||||||||||

50 | 100 | 104 | 95.0 | 15.65 | 17.1 | ||||||||||||

60 | 120 | 124 | 115.0 | 19.54 | 21.35 | ||||||||||||

HZPTM | 2.5 | 12 | 25 | A | 10~16 | 10 | 30 | 35 | 23.75 | 23 | 37 | 12 | 6 | M5 | P+6 | 4.39 | - |

14 | 10~17 | 10 | 35 | 40 | 28.75 | 25 | 5.77 | ||||||||||

15 | 12~21 | 10, 12, 15 | 37.5 | 42.5 | 31.25 | 30 | 6.41 | ||||||||||

16 | 12~22 | 40 | 45 | 33.75 | 32 | 7.09 | |||||||||||

18 | 12~26 | 10, 12, 15,20 | 45 | 50 | 38.75 | 38 | 8.28 | ||||||||||

20 | 12~28 | 50 | 55 | 43.75 | 40 | 9.59 | |||||||||||

22 | 12~30 | 12, 15, 20 | 55 | 60 | 48.75 | 44 | M6 | P+8 | 10.84 | ||||||||

24 | 12~33 | 12, 15, 20,25 | 60 | 65 | 53.75 | 48 | 12.10 | ||||||||||

25 | 12~35 | 62.5 | 67.5 | 56.25 | 50 | 12.78 | |||||||||||

28 | 12~42 | 12, 15, 20,25, 30 | 70 | 75 | 63.75 | 60 | 14.73 | ||||||||||

30 | 12~45 | 75 | 80 | 68.75 | 65 | 16.02 | |||||||||||

32 | 15~49 | 15, 20, 25,30, 35 | 80 | 85 | 73.75 | 70 | 17.40 | ||||||||||

35 | 87.5 | 92.5 | 81.25 | 19.52 | |||||||||||||

36 | 90 | 95 | 83.75 | 20.27 | |||||||||||||

40 | 100 | 105 | 93.75 | 23.15 | |||||||||||||

45 | 112.5 | 117.5 | 106.25 | 26.76 | |||||||||||||

48 | 120 | 125 | 113.75 | 29.01 | |||||||||||||

50 | 125 | 130 | 118.75 | 30.57 | |||||||||||||

3.0 | 12 | 30 | A | 12~19 | 12 | 36 | 42 | 28.5 | 28 | 45 | 15 | 7.5 | M5 | P+6 | 7.58 | - | |

14 | 12~22 | 12, 15 | 42 | 48 | 34.5 | 32 | 9.98 | ||||||||||

15 | 14~25 | 45 | 51 | 37.5 | 36 | 11.08 | |||||||||||

16 | 14~26 | 12, 15, 20 | 48 | 54 | 40.5 | 38 | 12.25 | ||||||||||

18 | 14~28 | 54 | 60 | 46.5 | 40 | 14.31 | |||||||||||

20 | 14~35 | 15, 20, 25 | 60 | 66 | 52.5 | 50 | M6 | P+8 | 16.56 | ||||||||

22 | 14~37 | 66 | 72 | 58.5 | 54 | 18.72 | |||||||||||

24 | 14~40 | 15, 20, 25,30 | 72 | 78 | 64.5 | 58 | 20.90 | ||||||||||

25 | 14~42 | 75 | 81 | 67.5 | 60 | 22.08 | |||||||||||

28 | 14~49 | 15, 20, 25,30, 35 | 84 | 90 | 76.5 | 70 | 25.45 | ||||||||||

30 | 14~52 | 90 | 96 | 82.5 | 75 | 27.68 | |||||||||||

32 | 18~52 | 20, 25, 30,35, 40 | 96 | 102 | 88.5 | 30.06 | |||||||||||

35 | 18~56 | 105 | 111 | 97.5 | 80 | 33.73 | |||||||||||

36 | 108 | 114 | 100.5 | 35.02 | |||||||||||||

40 | 120 | 126 | 112.5 | 40.01 | |||||||||||||

45 | 135 | 141 | 127.5 | 46.25 | |||||||||||||

Request a Brochure

and Samples

Request a Brochure

and Samples