Grip Chains

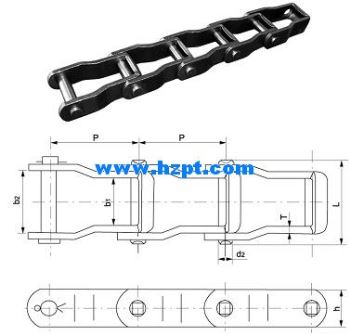

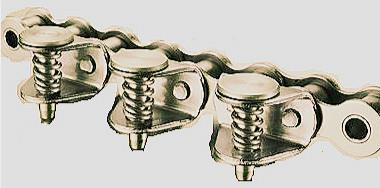

Grip chains with wear-resistant, corrosion-proof clamping elements are used for gripping, pulling and transporting thin-walled materials with large surface areas. Sensitive materials such as plastic film packaging, thin sheet metal, plastics and other hard sheet materials require careful handling to prevent damage during transport, positioning, feeding, pulling in or out, stamping, welding, filling, laminating, cutting, stretching, forming or sealing.

high-performance chains with excellent wear resistance

Minimal initial elongation due to optimum pre-stretching

High rigidity also enables applications in long machines

Basic chain versions are chemically nickel-plated / MEGAlife maintenance-free versions are available on request

Identical chain lengths (within the selected tolerance range) ensure excellent running characteristics in both synchronous and parallel operation

Differing levels of spring force allow an extremely wide range of materials to be gripped gently and held securely

Chains with restricted length tolerances can be produced

Recommended maximum running speed:

→ 2 m/s for the 1/2“ grip chain

→ 0.6 m/s for the 5/8“ grip chain

Different control geometry is required for higher running speeds.

iwis provides complete, ready-to-install solutions!

Further technical information can be found in our Grip chain product flyer.

Request a Brochure

and Samples

Request a Brochure

and Samples