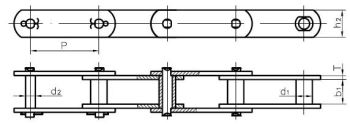

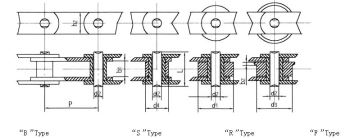

Forged bevel gear

TS16949 certified bevel gears manufacturing starts production from a forging, bar stock, or any other formed product such as a casting, depending on the strength requirements of the finished bevel gear. A forged blank is used when a superior strength to weight ratio, as well as better impact and fatigue resistance is necessary.

Forged bevel gears, cut gears, differentials, transmissions and drive systems. Gear cutting specialties include spur, helical, worm and worm wheel, splined shafts, internal I.D. - O.D. broaching of various sizes.

Focus

Design and Manufacture of Gearing and Machined Products and Assemblies

Net-forged Bevel Gears

Differentials

Transmissions

Angular Gearboxes

Rapid Prototyping and Market Introduction

Investment in Critical Production Capabilities

Efficient and Focused Engineering and Manufacturing

Commitment to Quality

Intelligent Cost Structure

Markets Served

ATV

Snowmobile

Marine

Construction/Utility

Government

Agriculture

Individual Gears

Gearbox Assemblies

Public Transportation

Logging Industry

Request a Brochure

and Samples

Request a Brochure

and Samples