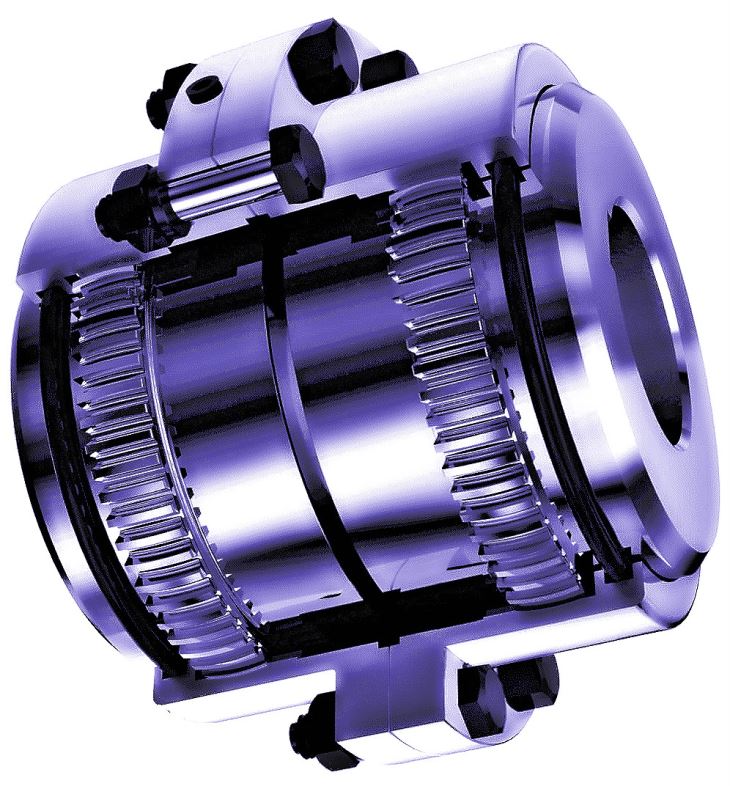

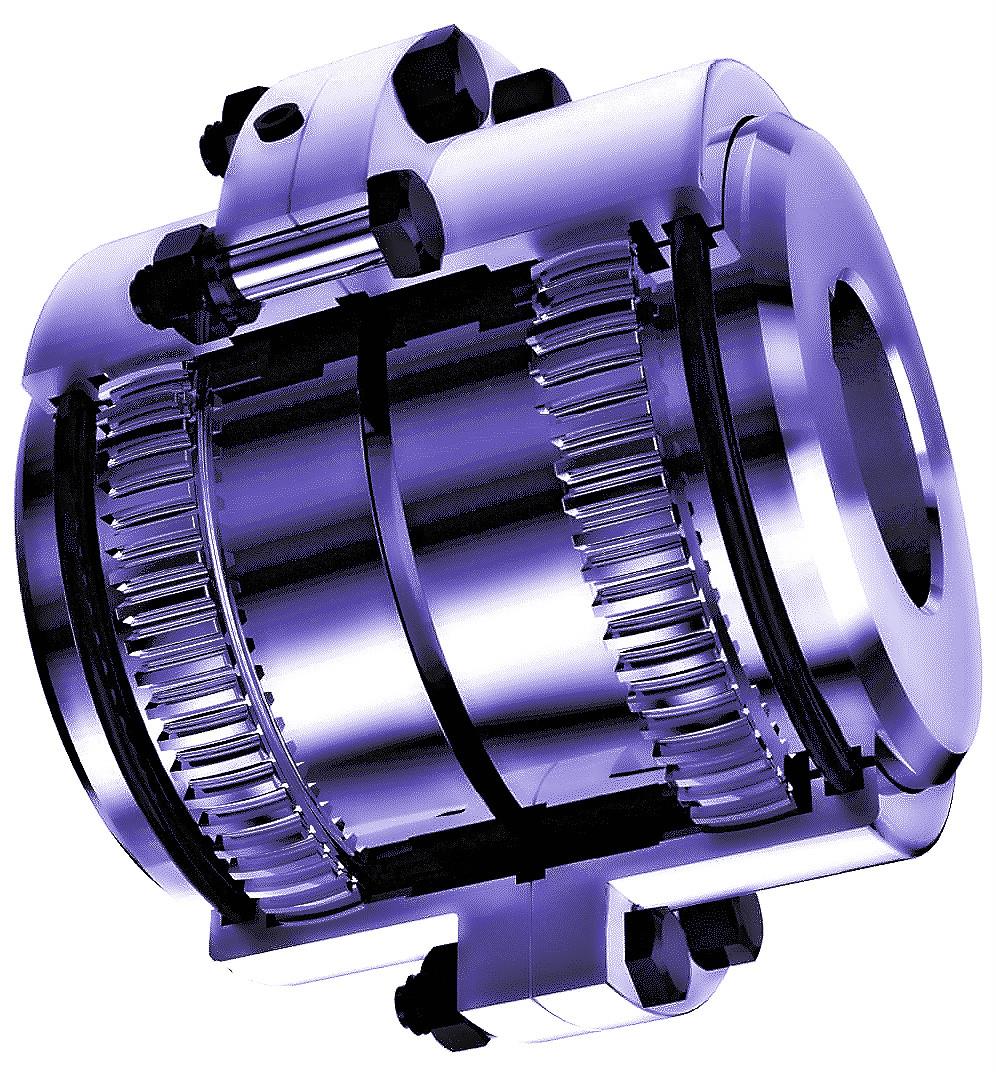

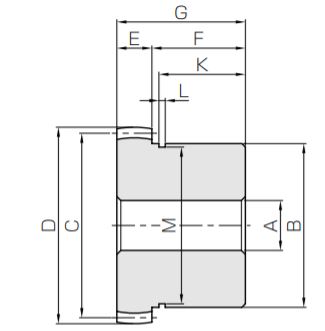

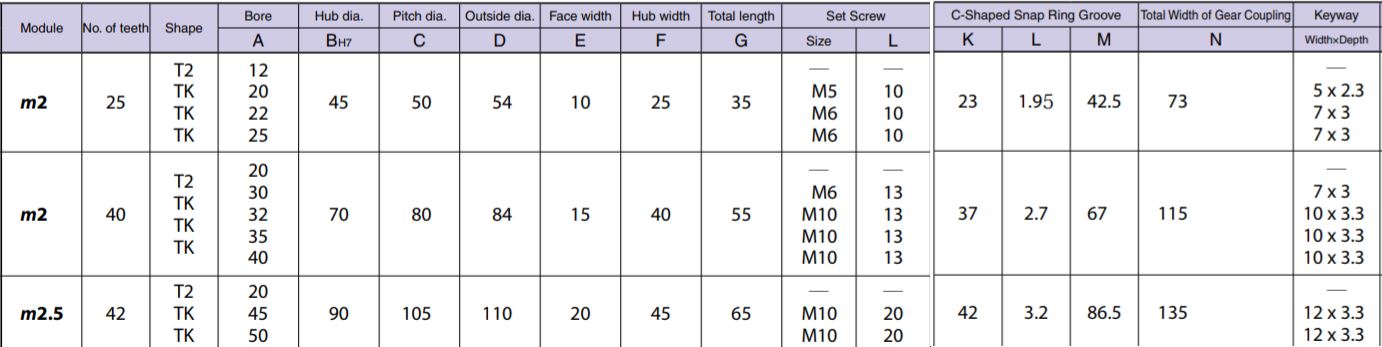

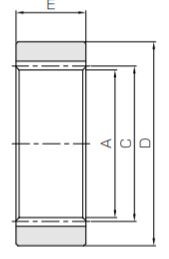

Gear Couplings Inner Hub and ring gear

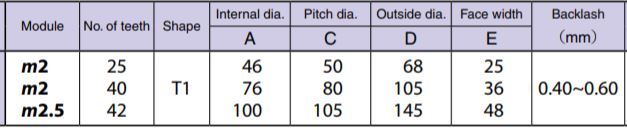

Easily removable gear coupling. Teeth use high-frequency hardening and surface uses chromate plating for high durability. Tooth type uses crowning machining and can be used up to a maximum of 5°. Pilot hole products and shaft hole complete products with keyway and tap available

Gear couplings transmit the highest amount of torque and the highest amount of torque in the smallest diameter of any flexible coupling.

Each coupling consists of two hubs with crowned external gear teeth. The hubs mesh with two internally splined flanged sleeves that are bolted together. Gear couplings accommodate angular and axial misalignment by the rocking and sliding of the crowned gear teeth against the mating sleeve teeth. Parallel misalignment is accommodated by having two adjacent hub/sleeve flex points. Gear couplings require periodic lubrication depending on the application. They are sensitive to lubrication failures but if properly installed and maintained, these couplings have a service life of 3 to 5 years and in some cases they can last for decades.

Gear Couplings’ triple-crowned teeth are crowned on the root, tip and face to articulate freely and minimize wear caused by misalignment. By eliminating tip-loading while reducing backlash and radial clearances,HEPT triple-crown teeth can help protect equipment from damaging loads.

Request a Brochure

and Samples

Request a Brochure

and Samples