Ground Helical Gears

Our precision machining capabilities satisfy a variety of strict customer dimensions and drawing specs. The manufacturing capabilities can hold overall external diameters of two feet or internal diameters of fifteen inches, including right and left facing helix angles in all sizes. These engineered helical gears can be produced with ferrous or non-ferrous materials with numerous secondary service options from heat treatment, tooth shaving and precision grinding

HZPT is well equipped to meet all of your helical gear needs, whether cut or precision ground. Our manufacturing capabilities include a wide range of sizes of custom made helical gears with quality levels up to AGMA Q15. Whether you need metric, diametral or other types of gears and splines, the team at HZPT has the knowledge and experience to produce the high quality gearing you need.

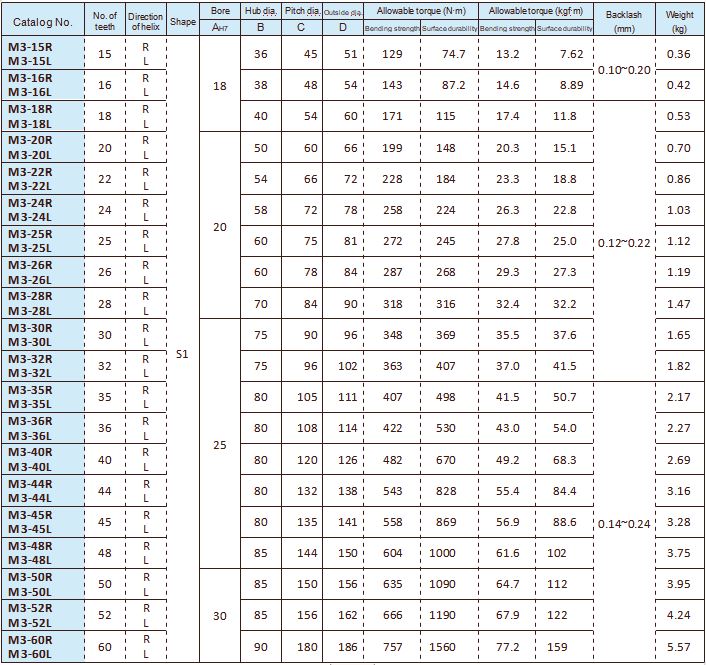

We provide some examples as followings for yr ref.

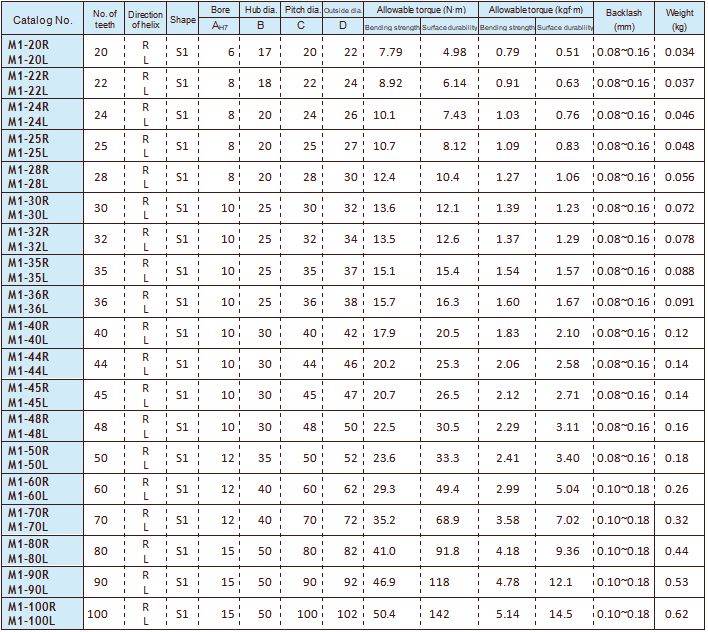

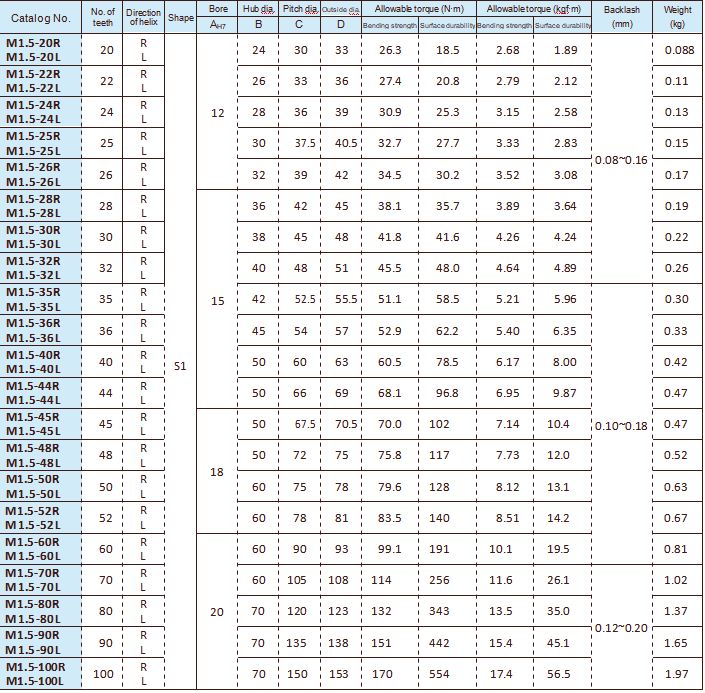

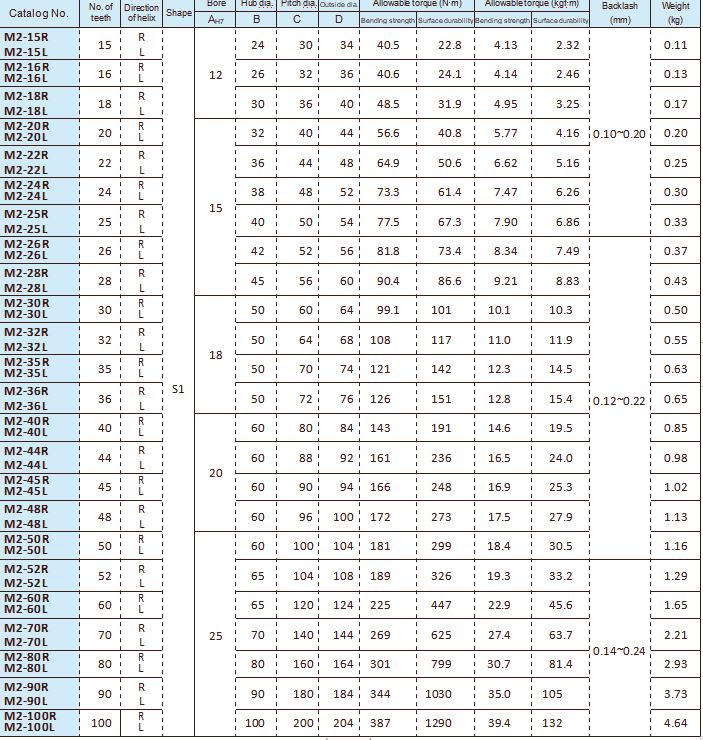

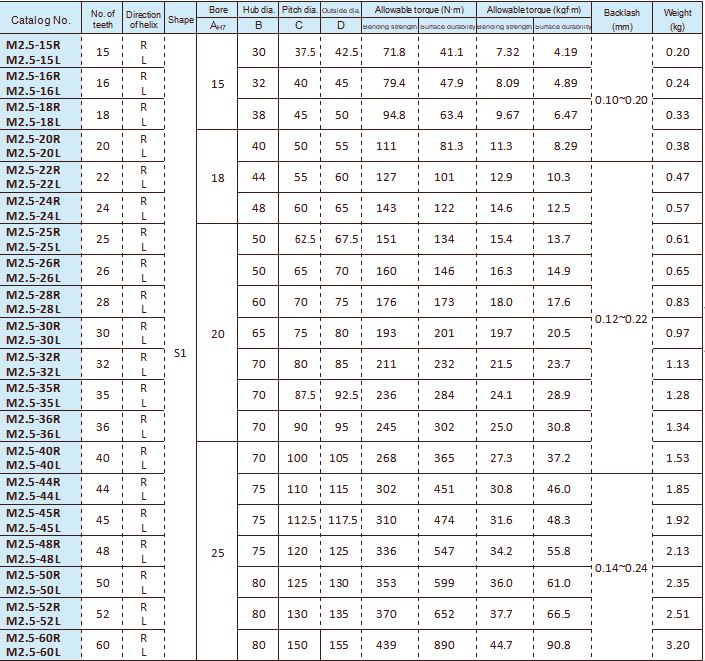

Specifications

Precision grade JIS grade N6 (JIS B1702-1: 1998)

JIS grade 2 (JIS B1702: 1976)

Reference

section of gear Rotating plane

Gear teeth Standard full depth

Transverse

pressure angle 20°

Helix angle 21°30'

Material SCM440

Heat treatment Thermal refinined, tooth surface induction hardened

Tooth hardness 50 ~ 60HRC

Face width (E) 8

Hub width (F) 10

Total length (G) 18

Screw offset (J) 5

① The allowable torques shown in the table are calculated values according to the assumed usage conditions.

② The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh.

③ These gears produce axial thrust forces.

④ Right handed and left handed helical gears in the same module are designed to mesh as a pair

Request a Brochure

and Samples

Request a Brochure

and Samples