Motorized Drum Roller FOR BELT CONVEYORS SYSTEMS SIZE 72 DIA.

Motorized Drum Roller DRUMMOTORS FOR BELT CONVEYORS SYSTEMS & CHECK-OUTS Motorized Drum Roller FOR BELT CONVEYORS SYSTEMS SIZE 72 DIA.

Motorized Drum Roller

DRUMMOTORS FOR BELT CONVEYORS SYSTEMS CHECK-OUTS

Motorized Drum Roller FOR BELT CONVEYORS SYSTEMS SIZE 72 DIA.

We can supply motorized drums with special voltage, in stainless steel, or rubber lagging.

The motorized drums for conveyor systems type RL 072,

MT 080, MT80S, MT 113, MT 113S,

products specially designed for motorizing conveyor systems

thanks to their easy assemblance and for their integration

into the conveyor.

OPERATION & MAINTENANCE

To install and work with motorized drums the following

instructions must be complied:

Motorized drums should normally be mounted horizontally

Motorized drums must not be

form of approved heat transfer system.

motorized drums must be dissipated,

damage may occur to the transmission

The conical tube insures the belt works centered

When Its are assembled in brackets

allow a gap ( 0.3 – 0.5 mm)between the end

bracket.

The belt should be adjusted just

load without slip.

Ensure the correct connection in accordance with the electrical

wiring schema.

To protect the motor from burning.

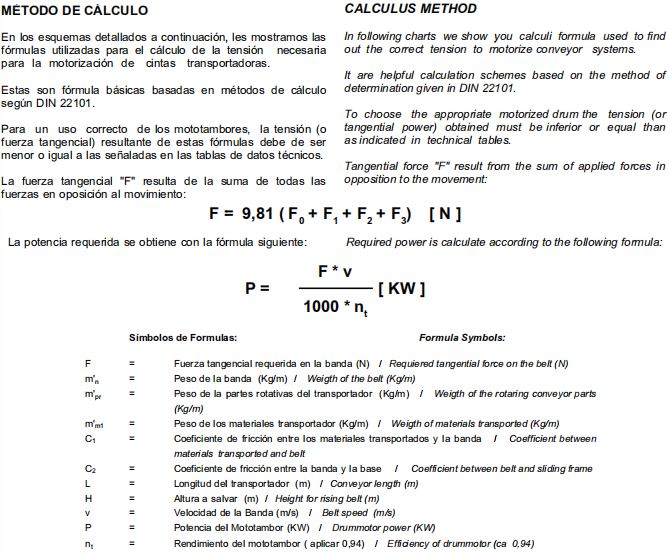

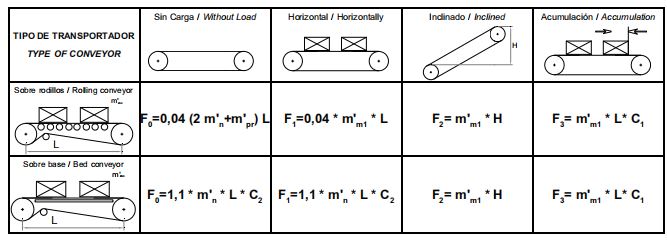

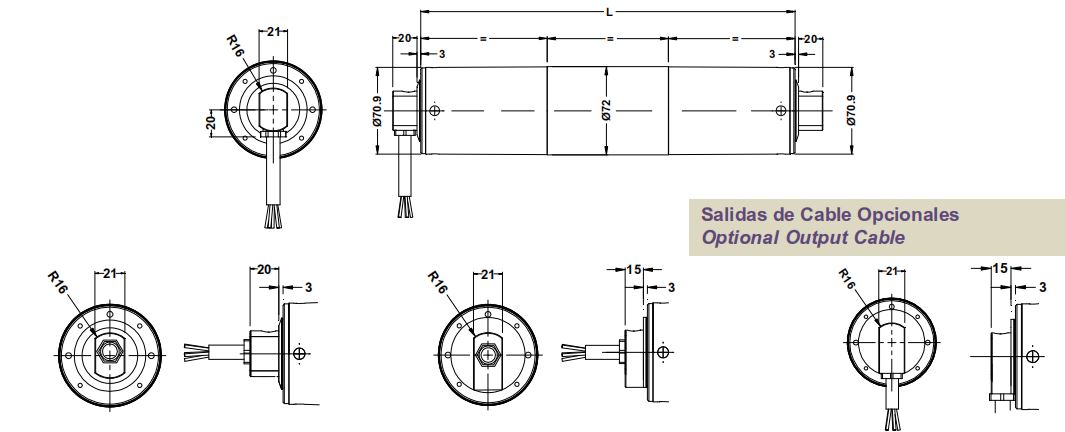

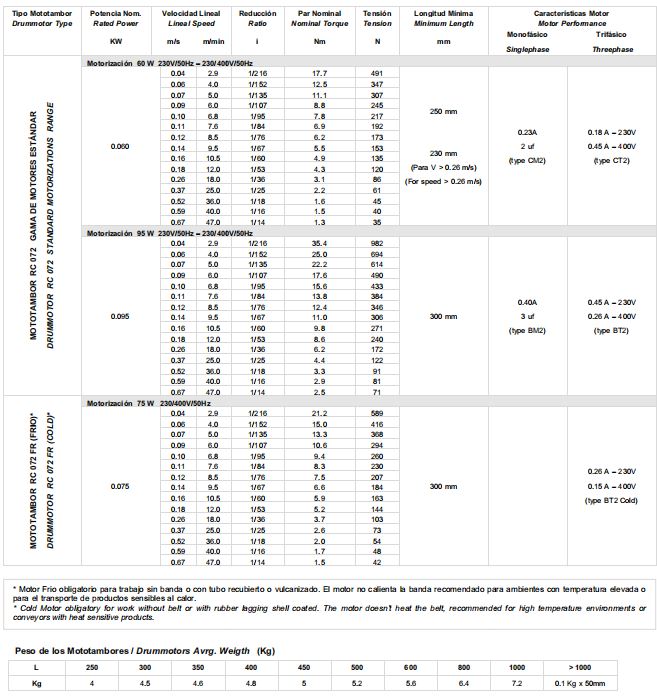

DRUMMOTOR Ø72

Diámetro : Ø72 mm

Velocidades : desde 2,6 hasta 46,9 m/min

Longitudes : desde 250 hasta 1.000 mm

Rated Speed : from 2,6 until 46,9 m/min

Shell Length : from 250 until 1.000 mm

TECHNICAL CHARACTERISTICS

• Asynchronous motor AC Three

phase.

• Insulation F Class.

• Lifetime Lubrication.

• Free Maintenance.

• Integral Thermal

• Planetary Gearbox with Steel Gears and Gear

Rim.

• Protection IP 54 or IP 66.

• Ambient Temperature

AVAILABLE OPTIONS

• Zinc Coated Steel Shell.

• ANSI 304 Stainless Steel Shell.

• Geometry of Tub

• Rubber Lagging Tube.

• Special Voltages of Motors.

• Brake motor.

• Different possibilities of Cable Connection.

APPLICATIONS

• Light Conveyors.

• Special Machines.

• Packaging Machines.

STANDARS

• EN 60034 - 1.

• CE

Request a Brochure

and Samples

Request a Brochure

and Samples