DK Conveyor Chains are available inside a variety of dimensions, roller varieties, and material and heat treatment. Moreover, the chains might be utilized for a broad array of application with our intensive selection of attachments and added options.

Classified by Dimensions

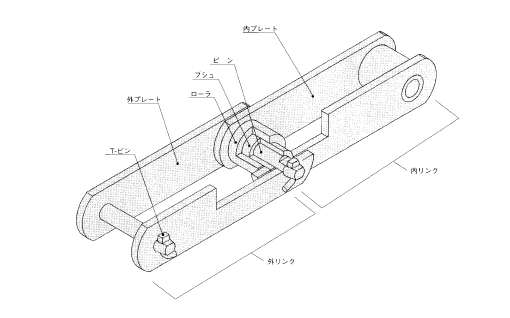

DK Conveyor Chains may be classified into typical, strong H-type and solid Z-type with reference to your size from the base chain.

The Regular Conveyor Chain is the simple type of DK Conveyor Chains, and lots of attachments, supplies, heat therapies, and so forth. can be found.

The Solid H-type Conveyor Chain was originally created like a chain for bucket elevators with enhanced power and it is now available in a series. A small-sized Robust H-type Conveyor Chain is nearly equal in strength to a large-sized Common Conveyor Chain, but because the dimensions and kind vary, sprockets aren’t interchangeable. Typically, Robust H-type Conveyor Chains are greater in power than Regular Conveyor Chains with about the exact same roller diameter.

Solid Z-type Conveyor Chains are further enhanced in strength than Powerful H-type Conveyor Chains by elevating the height in the inner plates, along with the sprockets are interchangeable in the event the nominal variety is the similar. Sturdy H-type Conveyor Chains are used in machines by which the plates slide to the floor, such as steady movement conveyors, because the inner and outer plates have the identical height.

However, Strong Z-type Conveyor Chains exhibit large

Classified by Roller Type

The rollers of a conveyor chain function not just to engage the sprockets moving the chain but in addition to rotate and travel on a rail, conveying posts with tiny frictional reduction. To meet several shapes of rails and prevent meandering, and so on., four styles of rollers, substantial roller, flange roller, medium roller and compact roller.

Moreover, for smoother rotation, we offer you large rollers and flange rollers with built-in bearings (BR and BF rollers, respectively), and UR and UF rollers with substantial clearances concerning the bushing as well as the roller to prevent the entry of foreign issues to the bearings. These rollers are frequently utilized in waste processing facilities.

In this catalogue, significant rollers, flange rollers, medium rollers and modest rollers are respectively expressed as R-roller, F-roller, M-roller and Roller S.